Ushio Europe will be attending FORMNEXT 2021 at Messe Frankfurt’s hall 12.1, booth A81, from 16–19 November 2021. As the leading international additive manufacturing conference and exhibition, FORMNEXT 2021 provides a huge networking opportunity for diverse businesses, such as the automotive, aerospace, mechanical engineering, medical technology, and electrical engineering industries.

For those interested in additive manufacturing and industrial 3D printing, Ushio has prepared its full product portfolio for the international visitors arriving in Frankfurt am Main. As a prominent manufacturer of industrial light sources, from ultraviolet (UV) to infrared (IR), Ushio’s Technical Development Team will be on hand to hold demonstrations and give technical advice.

Ushio offers advice and solutions for the following additive manufacturing processes

- Blasting surface treatment

- Directed energy deposition

- Heat treatments

- Optimization of production processes

- Photo-polymerization

- Powder bed fusion

- Processing of fibre-reinforced materials

- Sheet lamination

Ushio to demonstrate full infrared capabilities at FORMNEXT 2021

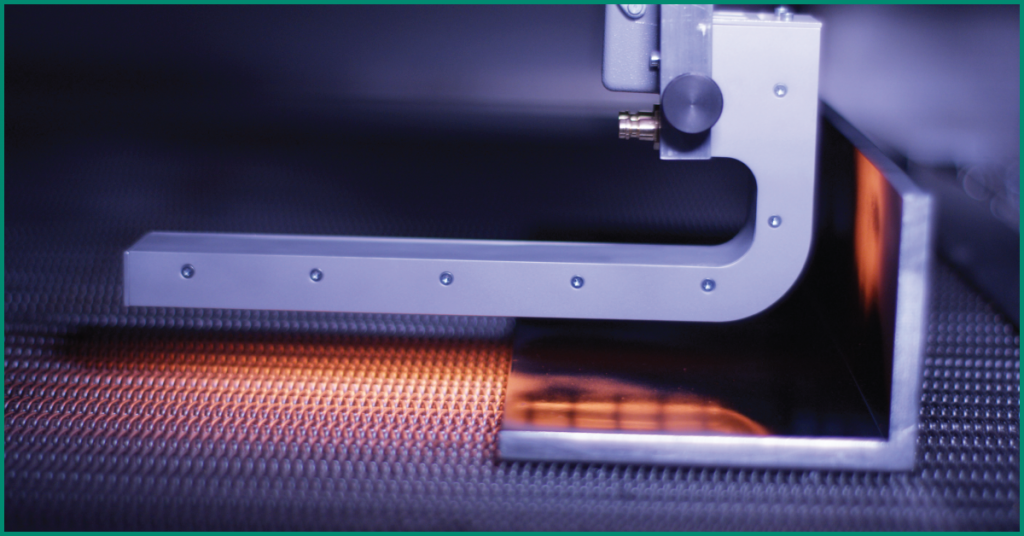

Find Ushio in hall 12.1, booth A81 for live demonstrations of groundbreaking industrial solutions. Widely implemented in the thermoforming of rubber and plastics, you will experience a live demonstration of Ushio’s versatile infrared heating equipment. Regardless of which application you strive to achieve, the power of infrared light has been harnessed by Ushio to enable your process to achieve maximum efficiency.

Ushio is a long-standing expert in the manufacture of customized IR heating solutions; however, the Germany-based engineers have also developed the IRtenser series of infrared heating modules and auxiliary components. Perfect for experimental processes, as well as standard heating applications, IRtenser represents the basic building blocks required in many heating processes. The standard portfolio consists of IR modules with wavelengths ranging from 0.8 –1.5 µm, and power densities ranging from 150–300 kW/m².

All IRtenser modules feature integrated cooling, a quick exchange mechanism for IR lamps, and are ready for immediate use.

Looking for somewhere to test your application ideas? Ushio’s IR Lab is ready for you!

You might be interested in an IRtenser or other heating solution, but sometimes it is better to see the product in action before committing to a bigger order. Ushio is able to customize its products to very specific requirements and can even replicate your own in-line processes at the Infrared Application Laboratory, in Steinhöring, Bavaria.

The IRtenser LC220 Demonstrator, which will be at FORMNEXT, seeks to show potential partners how a co-operation with Ushio facilitates joint research, development, and implementation. The unique L-shaped module is hooked up to a display which monitors the heating effect of IR irradiation achieved throughout treatment of various common substrates.

Ushio’s VUV excimer products improve surface treatments across the board

Vacuum-ultraviolet (VUV) excimer technology has become a popular method of removing organic contamination from substrates. VUV excimer is also used in various surface modification treatments, as an alternative to corona and plasma treatments, and for cold polymer cross-linking. Ushio’s compact ExciJet excimer system was specially designed for laboratory use and process development. The larger ExciJet systems have been optimized for production environments where fast, roll-through processing is used.

Common usage of excimer in industrial processes

- Alternative to corona and plasma-based surface treatments

- Biological modification of gases, liquids, and solids

- Disinfection & decontamination

- Homogeneous matting

- Increasing surface wettability for bonding inks, coatings, and lacquers to onto plastics and other materials

- Optical cleaning & ashing

- Photobonding (adhesive-free bonding)

- Photo-chemistry

- Pre-treatment for coating of composite materials

- Printing 3D electronics directly onto treated surfaces

- Surface activation or molecular modification

- UV curing

In the past, Ushio has provided successful excimer solutions to research pioneers, such as the Fraunhofer ILT PhotonFlex project, and original equipment manufacturers (OEM’s), like SteriLux SA. The beauty of excimer is its adaptability; able to be installed as an independent large scale solution or as a compact module which integrates directly into existing production lines.

- Broad length options & dimmable power ranges: from 55 mm 9 W lamps, up to 2 kW with our 2,600 mm lamps

- Unlimited lamp capacity, each individually calibrated for different spectra examination

- Phosphor-generated wavelengths from 170 nm – 350 nm

Ushio’s UniJet UV LED modules bring the cure to FORMNEXT 2021

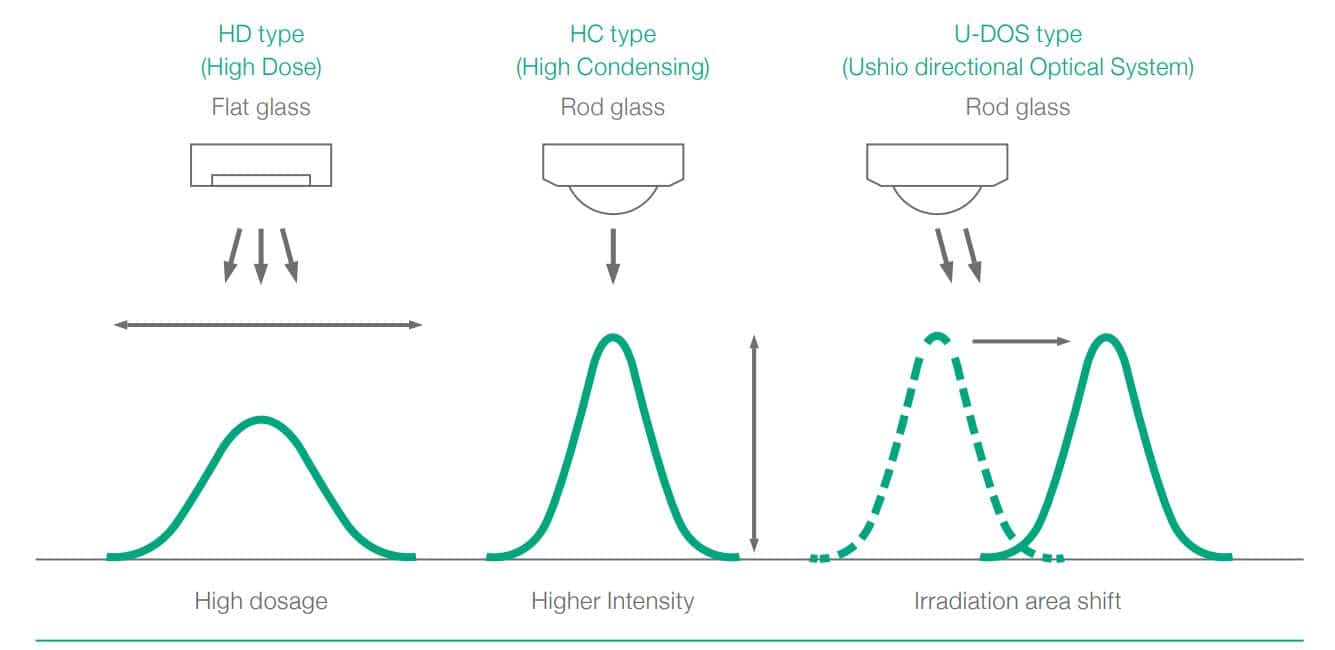

Ushio found success in the UV LED market, with its customizable UniJet modules. Designed for the highest performance in printing, curing, and image processing, UniJet has been launched in three distinct lines.

The UniJet A, E, and i-Series have been developed specifically with the commercial and industrial printing industries in mind. FORMNEXT 2021 visitors will have the opportunity to speak directly with Ushio representatives who have first-hand experience of using these devices, with the flagship UniJet E-Series taking centre stage on this occasion.

The entire range of Ushio’s UniJet UV LED modules holds a clear advantage over their traditional UV curing counterparts. With a total absence of mercury in the device, and the complete eradication of ozone emissions, UniJet offers safer operation conditions while ensuring unprecedented energy efficiency. The compact and easy to operate UniJet units are designed to remain fully operational for over 10,000 hours of use, and are available with either water or air cooling.

Join Ushio at FORMNEXT to find the customised solution for your production processes

Located at Messe Frankfurt hall 12.1, booth A81, Ushio Europe are ready to advise you on top quality additive manufacturing solutions. From deep UV to MWIR, Ushio has been long established as an integral part of the lighting world. With crucial developments across the spectrum, the Ushio experts will be ready to launch your production standards to the next level.

Already planning to attend FORMNEXT 2021? Get ahead of the game and set up a meeting with the team by clicking here, or by contacting your usual Ushio representative.

FORMNEXT 2021

Messe Frankfurt, Frankfurt am Main, Germany

16–19 November 2021

Visit the FORMNEXT website