Ushio provides testing facilities for infrared applications at various locations around the globe, with Ushio’s Application Laboratories taking root in Germany and Japan. During developmental phases, Ushio often asks clients to send some of their application materials to enable us to explore the perfect IR solutions to their needs. Some applications take place on a very large industrial scale, which can make replication of realistic conditions difficult in a laboratory scenario. For this reason, Ushio also offers to bring the lab directly to the client, with a new series of easy to use IR modules. The IRtenser series was introduced by Ushio to facilitate the research and development required to design customer infrared applications.

The modular infrared ‘building block’ system is geared towards ease of use, and can be applied to numerous different types of infrared treatments, alongside many of our long established solutions:

- Curing

- Thermoforming

- Printing

- Plastic welding

- Drying

- Preheating

Described by one of Ushio’s IR experts, Dr. Matthias Brandstetter, as the “Swiss Army knife of the infrared world”, the four existing IRtenser modules are fully customisable and adapt for easy application testing by Ushio’s clients. We are also embarking on a planning and development phase for further expansions to the series, as significant interest from industry leaders has proven the market is there.

Dr. Brandstetter explained that the logistical aspect of some application testing requires a solution that at the nerve centre of the clients’ needs: “General consensus is that while our own Innovation Lab brings the ingenuity of Ushio and our clients together, some applications take place on such a large scale that it makes sense for the lab to go to the client, rather than the other way around.” These efficiently designed, high powered IR-A devices aid the exploration of different lamp types, so you can find the best IR solution for you.

The IRtenser series enables in-house infrared application testing

While each of the IRtenser-series can be applied to a multitude of applications, Ushio will always be on hand to guide you, with almost half a century of experience creating IR heating solutions. We have previously advised and encouraged our modules to be used in the following ways:

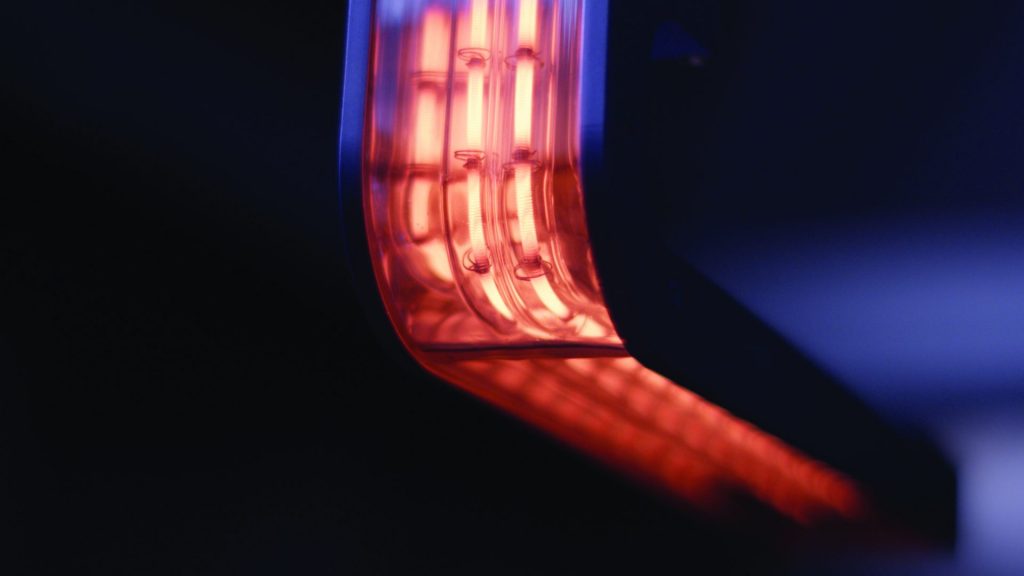

- IRtenser U300: Ideal for applications where space constraints are critical and a modular IR concept is required in order to create extended heating fields. This is particularly exemplified by applications such as 3D coating, fibre coating, and plastic forming. With 3 kW of power channelling through 3 bent IR lamps, a homogeneous heating field is generated to a power density of 150 kW/m2.

- IRtenser LC220+: This model brings an ultra-compact design to gleam 2.7 kW of power through a quartz window. The ultra-flat, L-shaped module allows for the simultaneous heating of two surfaces, which gives it an advantage in applications such as automatic fibre placement and various electronics industry processes.

- IRtenser R280 & R280+: These high power intensity 6 kW reference modules can be equipped with three different lamp types during process-of-elimination testing. Covering a multispectral IR range, this series is compatible with our EasyFit quick connection set. The R280+ model has an additionally integrated quartz window. These are best suited for exploratory applications that will eventually lead to a permanent solution or process.

Convenient research & development: your place, or ours?

Of course, if you are interested in using the Ushio Application Laboratory, feel free to contact us to arrange a meeting at one of our locations. Otherwise, you can ensure that the solution is formed on your very own premises, at your own pace, with IRtenser.

Reach out now to make further IRtenser enquiries, or email Thomas Haider and the team directly: ir@ushio.eu

For more information about the technical specifications of IRtenser, or optional additional hardware such as the IRtenser PSU1 power supply unit, and hybrid cooling systems, please visit the IRtenser product page.