Horticulture lighting

The greenhouse lighting known as HORTURION® has been an established name in the field of horticulture for almost two decades, and its HORTURION® HPS lamp serie as well as HORTURION® power supplies enjoy a worldwide reputation.

Originally sold under the brand name BLV, the HORTURION® series is now marketed under the brand name Ushio following the renaming of the companies BLV Licht- und Vakuumtechnik to Ushio Germany.

With undiminished intensity and great success, Ushio continues to invest in the research and development of conventional lamps: In 2020, with the HORTURION® intense, Ushio was the first company to launch an HPS lamp with 1150 W / 2400 µmol/s output.

This was followed, in July 2021, by the HORTURION® HPS 1000 W DE EL supra plus with 2180 µmol /s light output, and even surpassed in 2022 by what is currently the world’s most efficient HPS 1000 W lamp: HORTURION® HPS 1000 W DE EL suprema with 2200 µmol /s.

Ushio has also significantly expanded its production capacities to meet the increasing demand for conventional greenhouse lighting. In 2017, a new and state-of-the-art production facility was inaugurated at its branch Ushio Poland.

Customers from a wide range of growing sectors, from vegetable, fruit and flower farms to cactus growers, trust the quality and performance of the HORTURION® series.

References

In-house research & development center

Merging science and technology

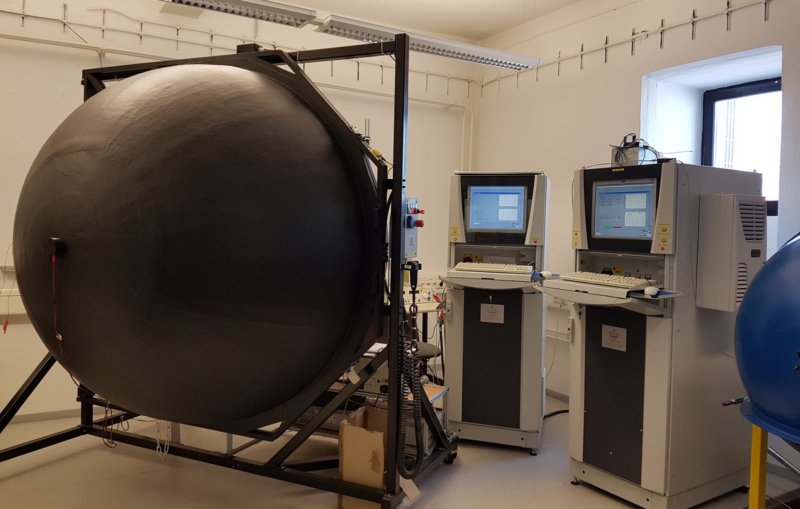

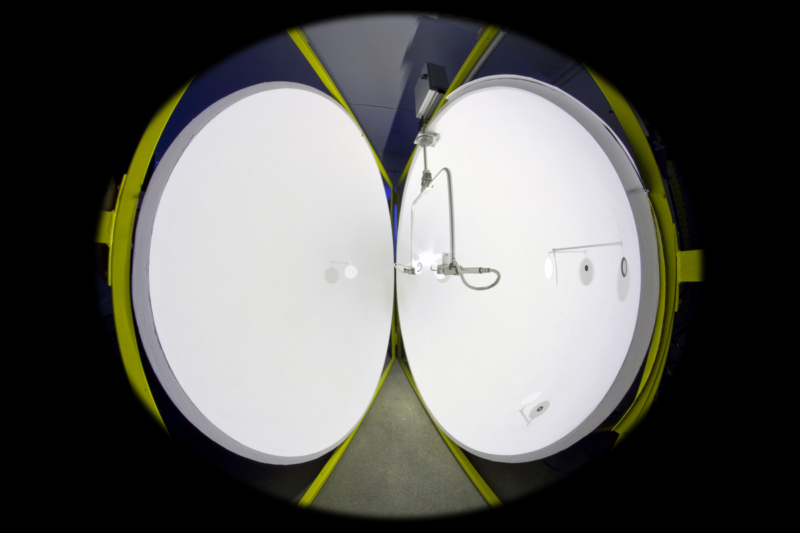

Our in-house engineering facilities are located at our company site in Steinhoering, near Munich. They are equipped with the latest technology and sophisticated devices for precise measurement and testing. This is where the first prototypes of the now world-famous HORTURION® series were manufactured more than a decade ago. To this day, the laboratories offer ideal conditions for innovations and world premieres like the first 1150 W / 2400 μmol/s HPS lamp, which was launched in 2020.

Ushio Germany GmbH, research and development center

For a long period of time the output of a 1000 W HPS lamp was restricted below 2000 μmol/s. The reason for the restriction was the gas pressure inside the burner and the technology used to ignite the lamp.

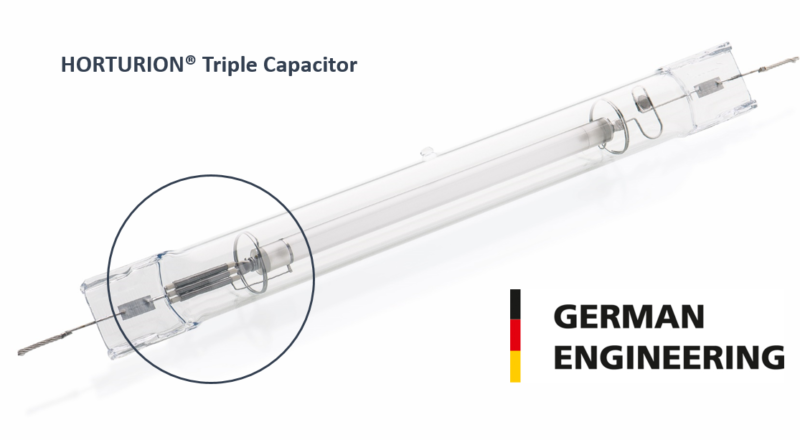

Our engineers optimised the gas pressure and developed a novel ignition technology, called HORTURION® triple capacitor. This opened the way for a new lamp generation, making the HORTURION® HPS one of the most efficient and most stable HPS lamps currently available.

Test installation with Ulbricht sphere

New production plant at Ushio Poland

Investing in the future

Our new production facility, inaugurated in 2017, has considerable capacity with a total area of almost 6000 m². At full capacity, 1 million lamps for professional greenhouse lighting can be manufactured here per year.

Production plant at Ushio Poland

With this capacity, we are not only a trustable partner for lamps of highest quality, but are also able to reliably produce and deliver orders with very high quantities for large-scale projects.

With joined forces of German engineering and European manufacturing, we are a trusted label providing our clients with products of high-quality, proven efficiency, and convincing lifetime helping them grow both their crops and their business!

More information

The light output of a high-pressure sodium (HPS) lamp is the key element determining its efficacy.

For a long period of time the output of a 1000 W HPS lamp was restricted to 1950 µmol s-1. The reason for the restriction was the gas pressure inside the burner and the technology used to ignite the lamp.

In these lamps the ignition current ran from one electrode through a conducting strip in the ceramics to the other electrode. The necessary flow of current from the electrode to the strip established a limit on the gas pressure inside the burner. Once the temperature was high enough the gas inside the burner ignited; the lamp glowed.

Some years ago, a new HORTURION® lamp was launched, which pushes the output from 1950 µmol s-1 to 2100 µmol s-1. By emitting 150 µmol s-1 more than a common lamp (+7.7 %), the HORTURION® 1000 W HPS sets a new benchmark in regard to efficiency. The technology is a quantum leap towards cost efficient high density production.

This new lamp generation was made possible through optimization of the gas pressure and the co-development of a novel ignition technology: the HORTURION® triple capacitor.

The triple capacitor directs the ignition current not only to the electrode but also directly to the strip. Once the gas is ignited, the triple capacitor closes the connection to the strip and prevents flow of current through the strip. Disconnecting the strip during operation is essential because a constant electric field would enable sodium atoms to diffuse through the ceramics. Diffusion changes the chemical composition of the gas in the burner, leading to early failure and a reduced light output.

Due to the triple capacitor technology the gas composition in the burner is constant. The stability of the gas composition in the burner reduces the light depreciation and guarantees the maximum light output throughout the life time of the lamp.

In thousands of tests the HORTURION® triple capacitor has shown reliable ignition, high light output and stable gas conditions inside the burner. Hence, the HORTURION® triple capacitor guarantees greatest reliability and very high output for the entire service life, making the HORTURION® HPS one of the most efficient and most stable HPS lamps currently available.

Ushio’s latest product brochures can be found on our downloads page.

To begin your product enquiries, please fill in the form on our contact page.