Ushio is heading back to Düsseldorf for 6th European edition of The Inkjet Conference (TheIJC), taking place at Crowne Plaza Düsseldorf-Neuss, on 29th and 30th October 2019. Representatives of Ushio will be present for the duration, at stand B14. TheIJC is a jointly held event from the European Specialist Manufacturers Association (ESMA) and Digital Direct Technologies, and is an increasingly important stop on the trade show calendar.

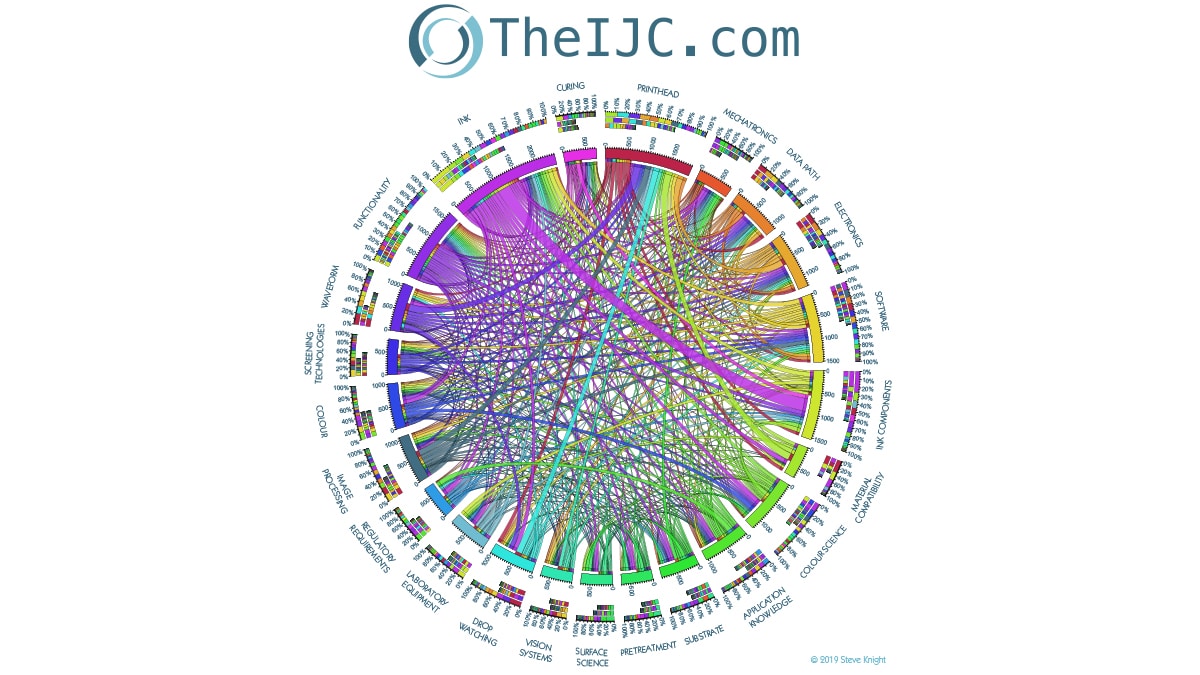

Since entering the inkjet engineering and chemistry scene in 2014, TheIJC has more than doubled in size, thanks largely to key industry players such as Ushio. As a leading provider of industrial lighting solutions to OEMs within the printing world, Ushio is finely attuned to TheIJC’s assertion that “inkjet is not one technology, it is a symphony”. The full symphony of interacting technologies is depicted in Steve Knight’s complex diagram ‘The IJC Circle’ (see below). To that end, Ushio Europe will be on hand to iron out the complexities of the many versatile solutions in the specialist lighting spectrum.

Focus topics at TheIJC made possible by Ushio components

- Curing (UV LED / conventional UV / IR)

- Pre-treatment (Excimer)

- Surface science (Excimer)

- Sensors (Laser Diodes)

- Application knowledge (Ushio’s Technical Development Team)

Hoping to capitalise on a recent surge of interest in specialist lighting solutions, Ushio Europe will be sending representatives who are able to advise on a multitude of printing applications. Aside from its exciting excimer surface activation offerings, Ushio’s UniJet UV LED modules hold a clear advantage over their traditional UV curing counterparts.

With a total absence of mercury within the device and the complete eradication of ozone emissions, UniJet offers safer operation conditions while ensuring unprecedented energy efficiency. The compact and easy to operate UniJet units are designed to remain fully operational for over 10,000 hours of use, and are available with either water or air cooling.

The air cooled UniJet E-Series arrives at TheIJC

- Mercury Free

- Ozone Free

- Energy Efficient

- Compact Design

- High Peak Irradiance

- Dimmable

- Long Life > 10,000 Hours

- Air Cooled

- Available Wavelengths: 365nm, 385nm, 395nm, 405nm

Ushio’s excimer technology exponentially improves ink adhesion

Excimer is unique because it provides irradiation without allowing an electrical discharge to make direct contact with the substrate surface. This means that the treated surface will hold on to any correctly applied ink, adhesive, or lacquer for longer. Ushio Europe has published a detailed educational resource which explains how useful excimer can be, especially when utilised within printing applications. The ‘Excimer: The Technology Explained’ resource is accessible by following the link at the foot of this article.

Surface Activation Energy Requirements

- Solvent inks: ≥ 34mN/m

- UV inks: 36 – 42mN/m

- Water-based colour systems: 38 – 50mN/m

- Coatings: 36 – 42mN/m

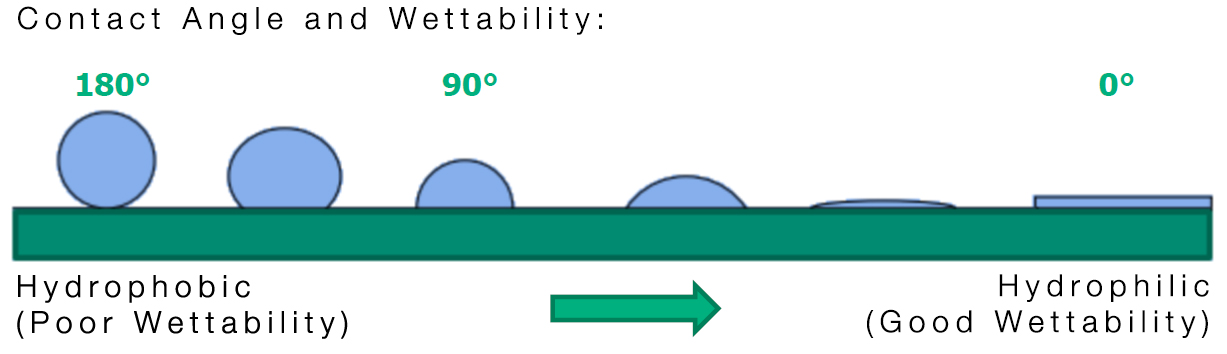

While the surface irradiation of polymers and other composite materials may be the most popular usage for excimer, the treatment is also applicable to almost any surface. Cleaning, coating, and bonding can also be significantly improved when applying excimer technology to silicon wafers, metals, and glass. In some cases, total hydrophilisation can be achieved in which wetting of the entire surface occurs. At this point, the contact angle of the liquid reaches zero degrees, transforming the drop of liquid into a liquid film.

Excimer irradiation ‘activates’ the surface by increasing the surface energy, which is measured in millinewtons per metre (mN/m). Surface energy determines the contact angle between a fluid and a solid surface. To ensure adhesion and homogeneous distribution, in applications such as printing and gluing, a smaller contact angle must be achieved.

When applied to printing and inkjet applications, the potential benefits are clear. Excimer has the power to make your ink stick to your substrate for far longer than other established techniques. Join Ushio at stand B14, to focus the conversation on to your production needs.

TheIJC.com

Crowne Plaza Düsseldorf-Neuss

Stand B14

29-30 October 2019

Further Reading

Ushio Excimer Irradiation Solutions brochure

Ushio UniJet UV LED Solutions brochure

Excimer: The Technology Explained learning resource

See a high quality rendering of ‘TheIJC Circle’ by Steve Knight, co-founder of TheIJC