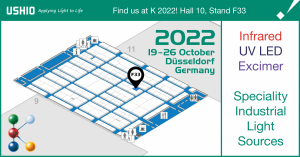

Ushio, a world leader in speciality industrial light source manufacturing, will exhibit its infrared lamps (IR), UV LED module, and excimer surface treatment technology at K 2022, the world’s number one trade fair for the plastic and rubber industries. The gigantic eight day event takes place in Germany, at Messe Düsseldorf, on 19–26 October 2022. Taking up residence in hall 10, at booth F33, Ushio is pleased to announce, its experts will be on-hand throughout to discuss applications in the plastic and rubber business.

Ushio returns to K 2022 after pre-pandemic success

After an inspiring experience at the show 3 years ago, the Ushio Europe made its K 2022 appearance a top priority. 224,116 visitors from 69 countries attended the last edition, with a staggering 64% (143,434) of those arriving to discover machinery and equipment possibilities. These statistics prove this enormous event to be important for a manufacturer whose products are heavily-involved in the treatment of plastics and rubber, such as Ushio.

Key K 2022 industrial lighting applications with Ushio

- 3D Printing

- Adhesive bonding

- AFP (automated fibre placement)

- Annealing

- Curing

- Drying

- Embossing

- Fibre winding

- Foil shrinking

- Food & beverage packaging

- Heating elements

- Infrared welding machines

- Injection blow mould pre-heating

- Matting

- Moulding

- Photo-bonding

- Plastic forming

- Plastic relaxation

- Pre-heating

- Priming

- Printing

- Resin transfer moulding (RTM)

- Rubber vulcanization

- Shaping

- Spot Welding

- Stretch flow moulding

- Stretching lines for film, filament etc.

- Surface Activation

- Surface cleaning

- Surface pre-treatment

- Tempering

- Thermoforming

- UV disinfection

Latest Infrared News for K 2022 visitors

By entering into a detailed discussion with Ushio about your specific needs, our experts can design an IR lamp with your exact needs in mind. For a general overview of Ushio’s infrared lamp collection, please find our Infrared Lamps brochure on the Downloads page. For the latest products, keep reading to learn about Ushio’s most recent innovations.

Infrared power doubles-up at K, with twin-tube lamp constructions

When space is tight, K 2022 visitors who are looking for maximum infrared heat treatment need to consider Ushio’s twin-tube IR lamps. Our German-engineered twin-tube lamps are effectively two powerful infrared emitters.

The twin-tube construction is exceptional for its mechanical robustness and stability, while the rapid heat-up time of just a few seconds makes it possible to switch the emitter on or off frequently. Ushio’s standard collection of twin-tube lamps available, but customisation is also possible. Ushio’s engineers and production teams are able to implement bespoke modifications on request, such as universal burning position, integration of ceramic reflectors, and waterproofing.

Ideal applications for Ushio infrared twin tube lamps

- Activating adhesives

- Drying of varnish & paper

- Heating of composite materials

- Heating or fusing of synthetics

- Heating prior to flash freezing

- Lamination & shrinking of foils

- Photovoltaics production

- Welding of synthetic fluid reservoirs

The high-power twin tube lamps from Ushio are available in single- or double-ended electrical contact form. With various filament designs available, you are free to select the short- (SWIR) or medium-wavelength infrared (MWIR) radiation output best suited to your application.

Visit our infrared twin tube lamp page here, or go straight to the IR twin tube lamp brochure here.

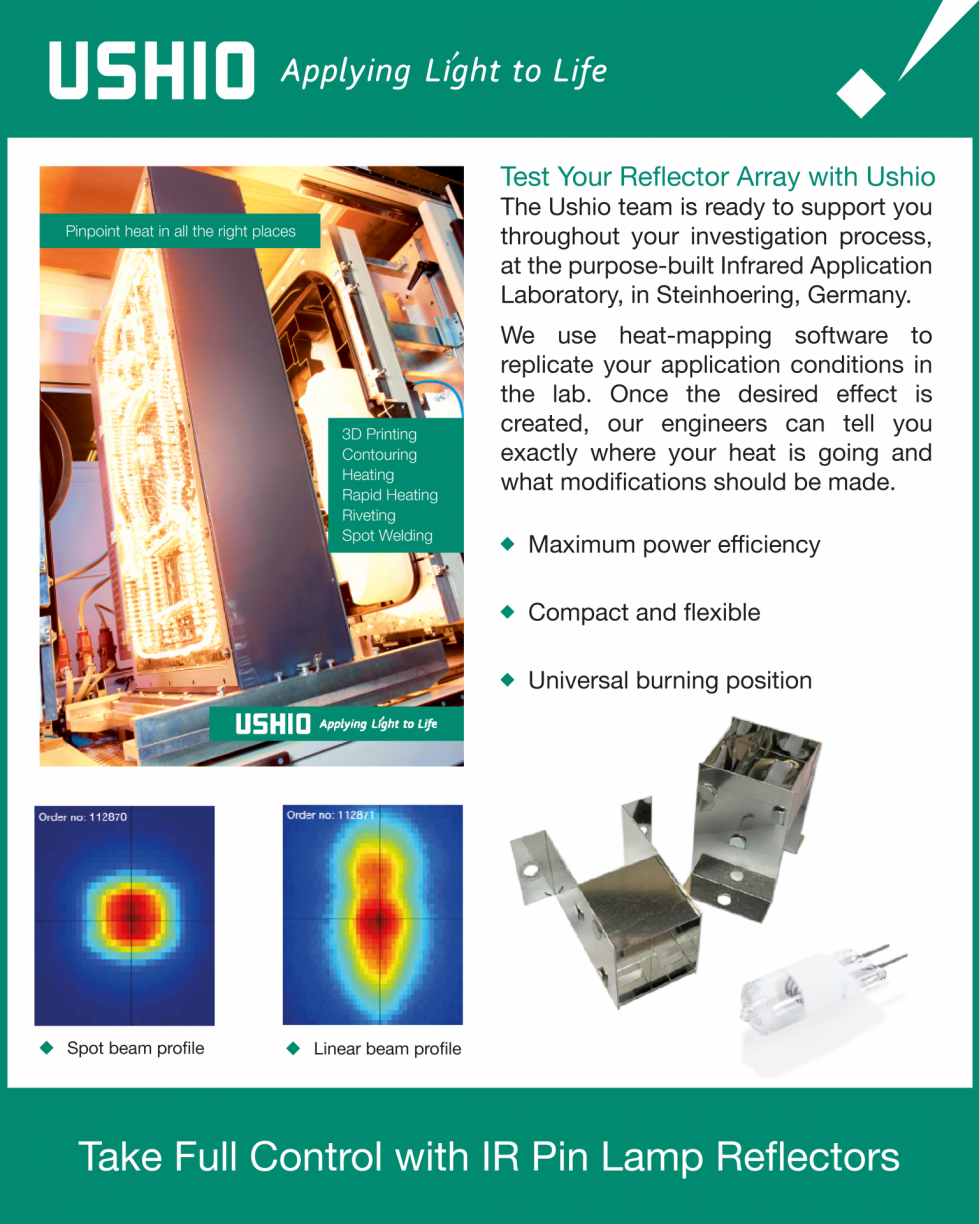

Infrared pin lamps are a versatile shaped lamp & spot welding alternative arriving at K 2022

Ushio’s single-ended, pin type IR lamps are powerful, yet compact infrared radiation sources. Some models are supplied with a reflective coating to focus IR radiation in the desired direction; however, our new modular reflectors allow operators more control over each lamp’s output. As an alternative to bent IR lamps, the pin-type lamps and accompanying reflectors have been designed to accommodate universal burning positions. Not only that, there is no limit to the number of reflectors that can be linked together.

Ushio’s infrared pin lamps & modular reflectors are extremely effective when used in:

- 3D Printing

- Complex Contour Heating

- Fibre Placement Systems

- Plastic Thermoforming

- Rapid Heating

- Riveting

- Spot Welding

IR pin lamp reflectors offer a compact and flexible solution for uniform heating applications that involve limited installation space or require a complex heating pattern. Distinct reflector designs also allow a choice of heat distributions. For some applications, focusing the IR emissions onto a single spot is ideal, such as static heating processes. Others require the concentration of radiation into a linear beam profile, suitable for conveyor belt or zone-heating applications. Any shape, pattern, or layout can be formed to provide pin-point heating patterns.

Ushio IR pin lamp reflector specifications

- Dimensions (spot beam): 28.8 x 25.3 x 48.2 mm

- Dimensions (linear beam): 52 x 33 x 54 mm

- Designed to treat substrates from a distance of 30–100 mm

- Compatible sockets are available to fit all Ushio IR pin lamps, from 80–200 W, and various colour temperatures

- Unlimited reflectors link together for uninterrupted irradiance

- Achieves uniform irradiance in any shape, pattern, or layout

- Significantly improves system efficiency and power density

- Reflector and pin lamps burn at any angle

- Extremely durable construction

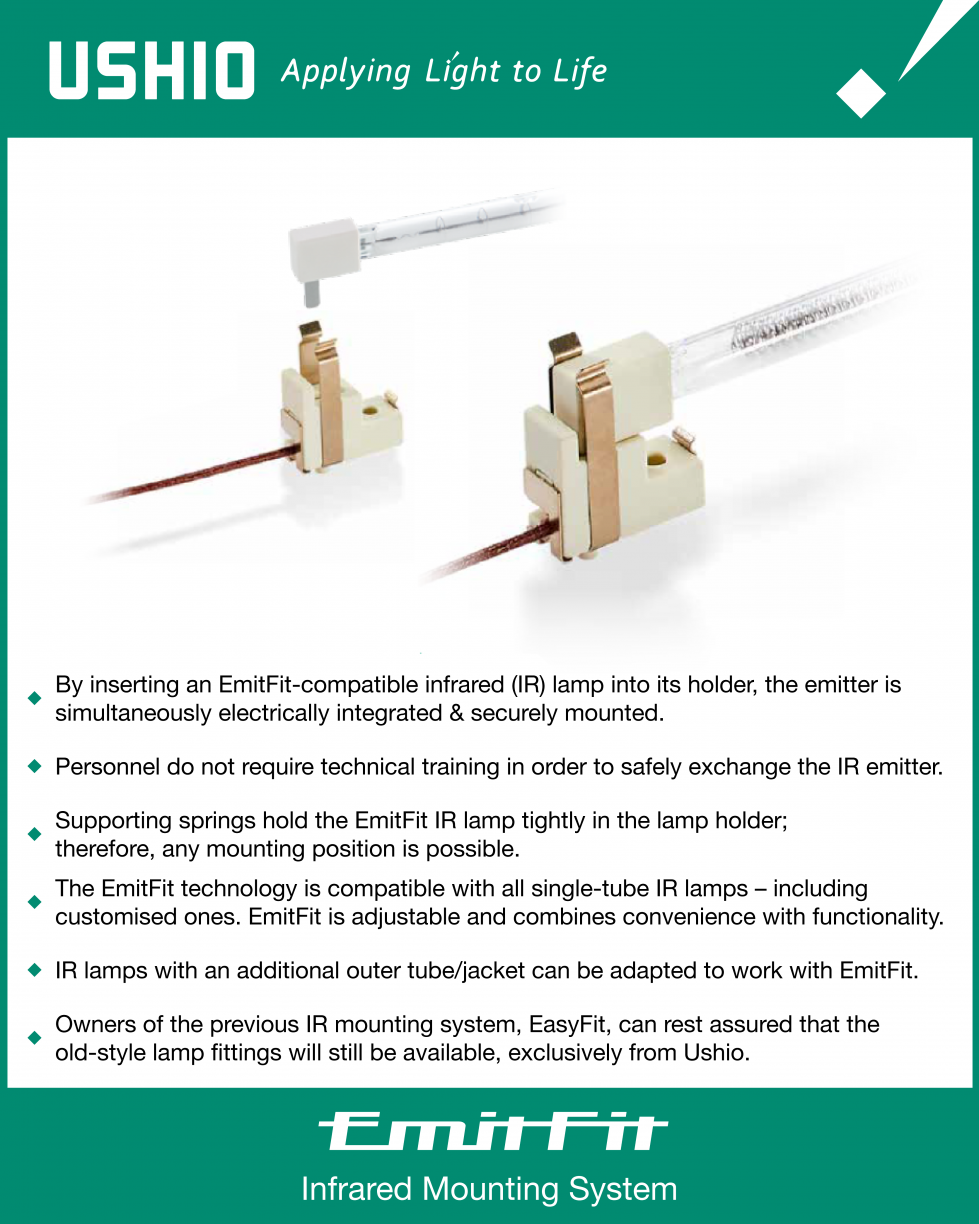

EmitFit simplifies plastics and rubber IR irradiation with quick-release lamp mount

Ushio presents the EmitFit series of fittings to electrically-integrate infrared lamps. Replacing the old EasyFit line, the upgraded quick-release ceramic base allows swift lamp exchange without costing a moment of production time. This new edition reduces the footprint of mounting systems and presents significant possibility for mount customisation, allowing OEMs to devote as much space to infrared heat treatment as possible.

Modular infrared heating equipment

Ushio focuses on customised solutions, and in the case of infrared (IR), we have developed a series of infrared modules and auxiliary components that serve as basic building blocks for many typical IR processes. The infrared modules are capable of wavelengths ranging from 0.8 µm to 1.5 µm, at a power density of 200 kW/m². All Ushio infrared modules feature integrated cooling, a quick exchange mechanism for infrared lamps, and are ready for immediate use. For your IR heating needs, Ushio proudly presents the IRtenser series. Customised versions or individual solutions are available upon request.

|

Device |

Name |

Description |

Dimensions (mm) |

Heating area (mm) |

Power (kW) |

|

IRtenser R280 |

Reference IR module with high power density. Multi-spectral infrared range. IR lamps with EmitFit quick connection. |

409x146x117 |

280×110 |

6 |

UV LED Modules

Ushio’s UniJet UV LED modules offer an effective alternative to UV curing with conventional ultraviolet lamps. Often used for curing UV-reactive inks, lacquers, and coatings, UV LEDs are particularly well-suited to applications that involve adhesives, potting compounds, and in printing applications. Typical applications include inkjet printing processes and curing of surface coatings or finishes. Ushio UniJet UV LED technology is used in high-quality graphic prints, printed electronics, battery assembly, and many others, such as security features in bank notes.

Ushio has decades of experience and invests continuously in research and development. With the newly optimised UniJet UV LED module series, namely the e-Series, iIV-Series and iC-Series, Ushio covers the complete spectrum of air-cooled UV-LED curing technology covering the demand ranging from compact, efficient and precise units to cutting edge performance and large scale devices. This makes the technology especially suited to industrial inkjet printing of graphics, and flexible electronics manufacturing.

The UniJet UV LED modules are characterised by a compact and lightweight design, dimmable output, stable peak irradiance, and homogeneous radiation distribution as well as a service life of over 10,000 hours. All modules are available with different UV doses and intensities and in various standard sizes.

For more information on our new UniJet UV LED modules, visit our Downloads page, or read on for a summary of each module series.

Ushio UniJet E series UV LED modules

Specially designed for pinning and 3D printing processes. HD (high dose) versions with high accumulation of UV irradiance over a wider area, HC (high condensing) versions for high peak irradiance through line-shaped focussing of the UV radiation. Flexible and optimised linking of individual modules with excellent homogeneity of light distribution, even at the point of connection between modules.

UniJet E series features

- Intensity of up to 7.2 W/cm² at a working distance of 5 mm

- 10–100% dimmable

- Optimised linking through frameless design

- Available in HD and HC version

Ushio UniJet iC series UV LED modules

Particularly lightweight and air-cooled modules for final curing applications. Due to their compact size and reduced weight, these LED modules are particularly suitable for applications on print carriages.

UniJet iC series features

- Intensity of up to 14.5 W/cm² at a working distance of 5 mm

- 10–100% dimmable

- Compact design, lightweight

- Optimised linking through frameless design

Ushio UniJet iIII series UV LED modules

Air-cooled modules with high-intensity and dose. Low intensity-loss even at longer working distances.

UniJet iIII series features

- Intensity of up to 17.4 W/cm² at a working distance of 5 mm

- 14–100% dimmable

- Reduced operating noise due to temperature-controlled cooling

- Less than 20% intensity loss up to a working distance of 15 mm

Ushio UniJet iIV series UV LED modules

By using highly efficient components, it was possible to achieve energy-saving operation while, at the same time, reducing the size of the modules. Due to their high intensity and high dose, the modules can be used instead of water-cooled models or conventional UV lamps.

UniJet iIV series features

- Intensity of up to 18.5 W/cm² at a working distance of 5 mm

- 15–100% dimmable

- Reduced operating noise due to temperature-controlled cooling

- Achieves approximately twice the UV dose compared to the UniJet iC series

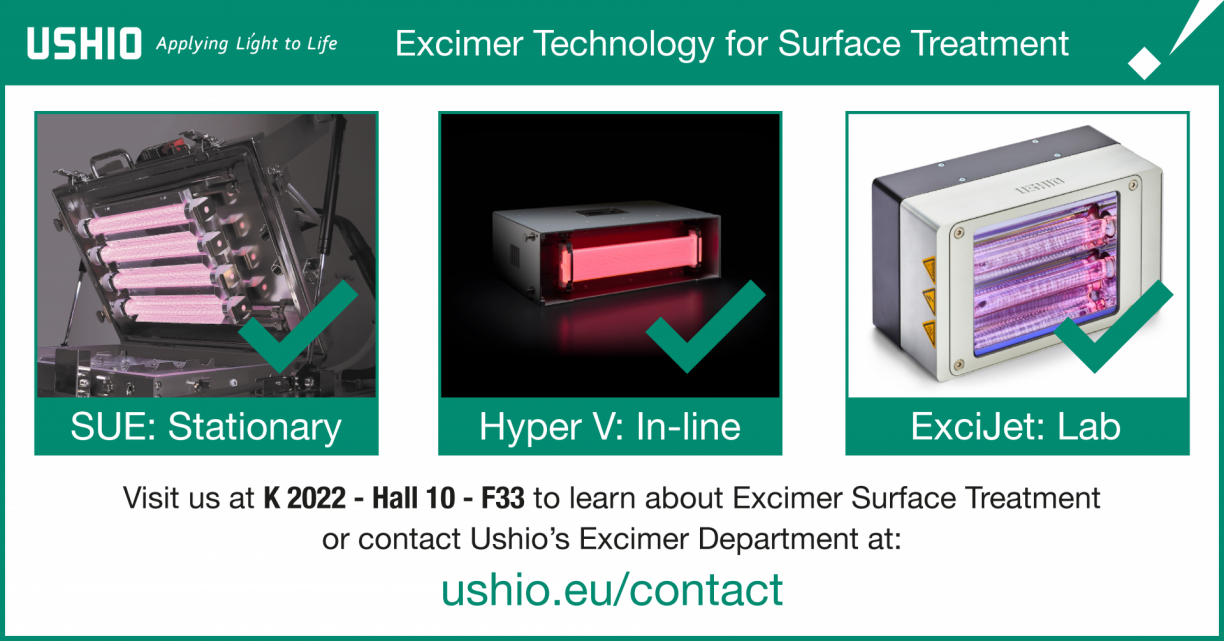

High-performance excimer modules from Ushio

Excimer treatment is a radiation-based process for surface cleaning and surface activation, which can be applied to a wide variety of materials such as plastics, glass or metals. In contrast to other methods, excimer irradiation is particularly precise, uniform and gentle and is, therefore, especially suitable for sensitive surfaces, such as membranes or wafers.

How does excimer treatment actually work?

Ushio’s state-of-the-art excimer technology uses radio frequency (RF) excitation of xenon gas to produce high-energy, narrow-band vacuum ultraviolet (VUV) radiation with a peak wavelength of around 172 nm. The two main surface applications for VUV radiation are the removal of organic contaminations and passivation layers, as well as the creation of hydrophilic chemical groups, such as carboxyl groups. In both applications, the effect is a result of the high-energy VUV radiation, which causes molecular scission, and oxidization by ozone that the radiation generates in the atmosphere between radiation source and surface. Ushio’s excimer technology has manifested in three types of excimer units that are designed for either research, lab applications, or pilot lines (ExciJet172 55-130); in-line treatment of substrates (HPV ST and HPV Series); and for stationary surface treatment (SUE Series).

Excimer tech pitched to K 2022 visitors looking for “gentle surface treatment”

Unlike the most common industrial alternatives, such as corona or plasma, excimer irradiation is an extremely gentle surface treatment process. This brings immense advantages when treating sensitive materials, such as mono-foils and wafers, and heat-sensitive substrates, such as PET, PE, PA, or extremely thin films.

While excimer treatment is based on radiation, corona and plasma surface treatments rely on high-energy, charged particles that also cause damage to the substrate, resulting in a roughly-treated surface.

Excimer treatment is fast-becoming an essential intermediate production step in many industrial applications, because it removes contamination and passivation layers, while simultaneously forming hydrophilic molecular groups. This combination enhances electro-negativity and leads to a higher surface energy. The result is a substantial improvement to printability, coating adhesion, and bonds between substrates.

Due to the absence of an electrical field, excimer does not suffer from the dust contamination associated with corona treatment, and can be applied to all electronics, which would otherwise suffer from static-related issues associated with a discharge.

Splitting excimer’s industrial applications into three blocks: surface cleaning, surface activation, and optical bonding, the Ushio team is able to deliver the facts and reveal tangible application potential in numerous industrial sectors. You will receive background information on the physical processes, effectiveness on different materials, as well as extensive knowledge on integrating excimer modules into your process structure and production line.

Benefits of excimer lamps over traditional industrial surface treatment processes

What does excimer do better than corona treatment?

- No undesirable back-side treatment

- Conductive materials can be treated, e.g. metal foils. Corona treatment is unsuitable for this.

- Homogeneous & precise

- No surface roughening

Where does excimer improve on flame treatment?

- No contamination of the substrate or environment

- Free of burning residues

- Does not produce NO2 (nitrous dioxide)

- Zero heat stress

Why is excimer preferred over atmospheric plasma treatment?

- Homogeneous and precise

- No surface roughening

- Economical on large web width

Visit the Ushio team at K 2022 stand F33

If you can’t wait to speak to the Ushio team at K 2022, you can get up-to-date with Ushio’s infrared, excimer, or UV LED technology by downloading our latest brochures. If you are already in a position to make an enquiry regarding Ushio’s plastic and rubber industry solutions, you can reach the Ushio team here.