At the world’s leading trade fair for the printing industry, DRUPA, taking place May 28 to June 7 at Messe Düsseldorf, Ushio – Hall 8a Stand C27 – will present its wide light source portfolio for the printing industry. A particular focus will be on its UV LED solutions, optimized for precise, fast curing and fast drying of inks, lacquers, and coatings for a wide range of printing processes including screen, inkjet, digital, intermittent and rotary letterpress processes.

UniJet S series for intermittent letterpress and offset printing press

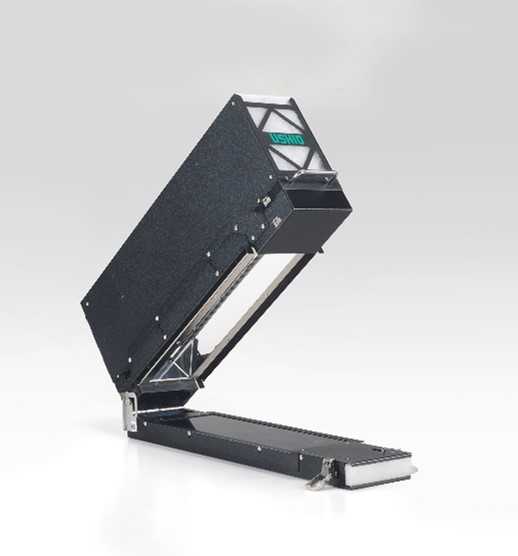

Ushio proudly announces the debut of its newest innovation, the UniJet S series. Engineered specifically for intermittent letterpress, rotary letterpress, and offset printing presses, with the added flexibility to be mounted on flexo printing machines, the UniJet S series sets a new standard for performance and efficiency in the industry.

Designed with the needs of printers and on-site operators in mind, the UniJet S series not only reduces power consumption but also significantly enhances work efficiency. Key features include a split lighting function enabling individual activation of UV-LED boards, simplified maintenance for glass replacement, a reinforced structure preventing the module from ink and dust contamination, as well as advanced temperature rise detection capabilities.

UniJet Series for Line Curing

Ushio is presenting the established E-Series, which is especially designed for pinning and 3D printing processes, as well as its newly optimized UV LED high power unit UniJet iIV and UniJet iC series, characterized by a compact and lightweight design, dimmable output, stable peak irradiance, and homogeneous radiation distribution as well as a service life of over 10,000 hours. The modules offer different UV intensities and are available in market well-known sizes.

Ushio’s UniJet UV LED modules offer an effective alternative to UV curing with conventional ultraviolet lamps. Often used for curing UV-reactive inks, lacquers, and coatings, UV LEDs are particularly well-suited to applications in printing applications of almost every kind.

Typical applications include inkjet printing processes and curing of surface coatings or finishes. Ushio UniJet UV LED technology is used in high-quality graphic prints, printed electronics, battery assembly, and many others, such as security features in bank notes.

Ushio has decades of experience and invests continuously in research and development. The company covers the complete spectrum of air-cooled UV-LED curing technology ranging from compact, efficient and precise units to cutting edge performance and large-scale devices or module combinations.

MIDORI™ Series for Spot Curing

The MIDORI™ UV Spot Cure LED Light Source has already proven itself in the USA. The Midori™ ULB-50sc series UV (365 nm) and UV (405 nm) LED light sources are premier fiber optic illuminators for spot curing adhesives or coating applications where bench space is a premium. This feature-rich solid-state light source is extremely compact, energy efficient and easy to use. It is compatible with most existing lamp-based system processes and outperforms them in terms of cost-effective photo-curing solutions.

IR light sources for effective drying – beyond standard

At its stand, Ushio will likewise present its portfolio as well as options for customised IR solutions for the wide range of printing processes with water-based inks.

This year’s hot topics are:

Twin Tube IR Lamps –Two quartz tubes, fused together, achieve new levels of durability and increased performance in small spaces. Ushio’s famous customisations include integrated reflectors, universal burning position, and waterproofing.

Gold Coated IR Lamps – Lamps with gold coating on the outside of the quartz glass optimise power density through maximum reflectivity and direct the emission precisely onto the target material. Various circumferences and coverings are likewise possible. Golden coated lamps are a perfect alternative to temperature-stable white coating for application areas where energy saving, optimisation and efficiency are the goals.

Bended lamps – Ushio has developed an advanced production process which has also seen the arrival of highly sophisticated bent or curved single and twin tube lamps. The advantage of these lamps is the possibility to combine them in a variety of ways to provide stable and homogeneous heating fields.

If our popular U-shaped glass tube is not quite to your needs, it is possible to request different shaped designs.

Extra-long twin-tube IR lamps – Ushio is expanding its IR lamp portfolio with twin-tube lamps up to 5 meters long. These lamps offer a higher power density and flexible connection and control options with less installation effort. The positioning of the temperature-sensitive pinching area outside the heating zone makes them particularly suitable for applications where wide webs need to be heated. Waterproof versions are likewise available.

Reflectors for Pin Lamps – As a modular alternative to expensive, custom-built, bent IR lamps, these reflectors improve system efficiency and power density. With the help of these reflectors, the beam profile of pin lamps can be directed to a point or linear shape. Any pattern or layout can be made to uniformly focus the IR heat exactly where and when it is needed.

EmitFit – a quick-release ceramic mounting system for swift IR lamp exchange and reduced production down-time. The new design reduces the fitting size to maximize the area devoted to IR irradiation.

Excimer Technology for Surface Treatment and Bonding Processes

Apart from the range of UV LED modules, Ushio will present its Excimer technology, a radiation-based low-temperature method that allows to optimise the surface conditions in all types of printing applications resulting in higher quality graphics and better looking surfaces.

Ushio Excimer modules are used for surface cleaning, surface activation and surface functionalization and can be applied to a wide variety of materials such as plastics, glass or metals. In contrast to other technologies, excimer irradiation is particularly clean, uniform and gentle and is, therefore, especially suitable for sensitive surfaces, such as thin films and webs.

Ushio offers two excimer product series: the Hyper V series, which is specially designed for inline treatments and the SUE series, which has been designed for stationary irradiation.

With its ExciJet172 55-130 module Ushio offers a very small Excimer module for testing purposes in laboratory facilities. It allows customers to treat substrates under real conditions either in our own excimer application laboratory or on site. The small dimensions of the module allow easy and flexible installation in test set-ups or pilot lines.

Meet Ushio at DRUPA 2024

If you are interested in making an appointment with one of our experts on site at DRUPA or are interested in contacting us in any other way, please write to us at the following link https://www.ushio.eu/contact/

DRUPA 2024

Messe Düsseldorf

Hall 8a Stand C27

28 May – 07 June 2024