IR-B / SWIR

Some Ushio products emit infrared B (IR-B) radiation with wavelengths ranging from 1,400 nm to 3,000 nm for heating processes. IR-B radiation is used for various industrial processes.

All Ushio IR lamps are manufactured using the highest quality materials, and many of them are handmade, meticulously constructed by our elite production team.

Ushio’s IR-B lamps are designed in such a way to obtain a specific power at a certain voltage. The operational lifetime of your lamp depends directly on that. A frequent load change in voltage can result in a shorter lifetime for your lamp. Operation at over-voltage will decrease the lifetime significantly. Ushio can adapt the production and handling of any IR lamp in such a way that its lifetime will not be affected by load changes. If you let us know early on, our experts can design an IR lamp with your specific needs and application in mind.

Fully Customisable Specifications

- Available from 80 W – 16,000 W

- Colour temperature from 800 K – 3,200 K

- Specific power densities available from 10 W/cm to 270 W/cm of lamp heating length

- Precision area heating up to 1000 kW/m²

- Available with or without integrated reflector; allowing the operator to direct IR radiation instead of wasting misdirected waves at a loss

- Client-specific modifications or entirely new IR lamp developments are available on request

- Radiation wavelength adaptation for application optimisation by use of additional tubes or optional tube coatings

- Vacuum and water resistant lamps are available

Unmatched Performance & Efficiency

- Short reaction time: 1 – 3 seconds, ensures very little delay during switch-on, power control adjustments, and switch-off

- Efficient short and medium wavelength lamps convert more than 92% of the total electrical power input into IR radiation

- No heating of the surrounding air through dissipation of short-wave radiation

- High-quality quartz tubes guarantee long term mechanical and thermal robustness

- All Ushio IR lamps are dimmable and compatible with major power controllers

- Full integration into compact OEM machines possible due to the small dimensions of the IR lamps

- Average lifetime up to 5,000 hours at rated voltage

Only The Highest Quality Quartz Glass

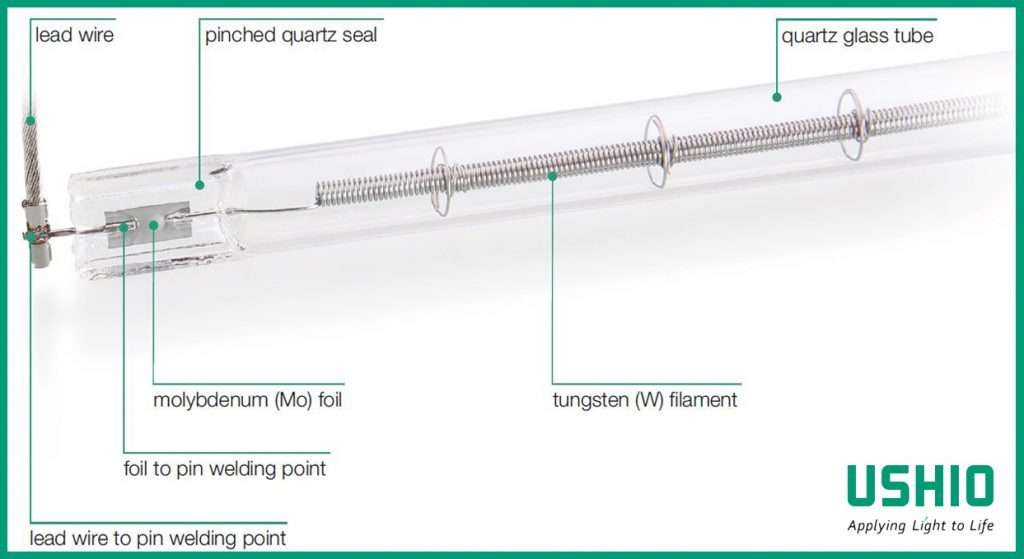

All Ushio IR lamps are made using quartz glass for improved thermal shock resistance and high softening temperature. The mechanical and electronic connection to the lamp base is located at the end of the glass chamber and is fixed by special cement to a pinched or round sealing section of the quartz glass.

The Molybdenum Foil Bridge

Electricity is able to pass through the seal thanks to the implementation of a molybdenum (Mo) foil bridge welded to the tungsten filament and contact pin. The Mo-foil is required because tungsten (W) possesses a thermal coefficient ten times that of quartz glass, which prohibits a direct bond between the two parts. The introduction of the foil allows a thermally stable, vacuum sealed connection within the quartz glass which will remain intact for the duration of the lamp’s operational lifetime.

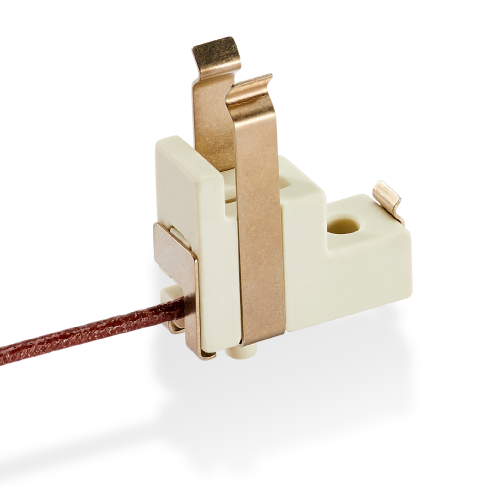

Ceramic Isolation

At the extremities of the lamp, an outer pin mostly shielded by a ceramic base facilitates the electrical connection. The ceramics used by Ushio have high heat capacity with a high level of heat conduction and, aside from mechanically integrating the lamp to the equipment and power supply,

the corrosion-resistant base serves as an electrical isolator.

Plug-And-Play: The EmitFit Way

A unique, optional feature of Ushio IR lamps is the proprietary EmitFit ‘plug-and-play’ technology. With this technology, even the exchange of customised lamps becomes an extremely fast and easy task. EmitFit is individually adjustable and combines convenience and functionality. The lamp is both electrically attached and mechanically mounted at the same time, and no special training is required to get your lamp up and running.

Visit the Ushio Europe downloads page to receive your free copy of the Infrared Lamps for Diverse Industrial Applications brochure.

To begin your sales enquiries, please fill in the form on our contact page.

Dispersing The Heat Load

The filament and the Mo-foil transmit the current while simultaneously dispersing the heat produced by the emitter during operation. The quartz tube can reach temperatures of 600°C to 900°C, and the persistent channelling of this heat load will raise the temperature of the foil and seal

considerably.

Heat Management Is Key

In order to preserve the operational lifetime of the emitter, the foil and seal must not exceed a temperature of 350°C. However, depending on the application in question and various environmental factors, the end user must implement a suitable cooling system to ensure the maximum operational temperature is not exceeded.

Visit the Ushio Europe downloads page to receive your free copy of the Infrared Lamps for Diverse Industrial Applications brochure.

To begin your sales enquiries, please fill in the form on our contact page.