What is excimer?

The term excimer refers to a temporary atomic state in which high-energy atoms form short-lived molecular pairs, or dimers, when electronically excited. These pairs are called excited dimers. As the excited dimers return to their original state, the residual energy is released as a ultraviolet C (UVC) photon.

In the 1960s, a new portmanteau, excimer, emerged from the science community and became the accepted term for describing excited dimers.

By definition, the term excimer refers only to homodimeric bonds between molecules of the same species. For example, in a xenon (Xe) excimer lamp, high-energy Xe atoms form excited Xe2 dimers. These dimers result in the release of UV photons at the wavelength of 172 nm, which is widely used in industry for surface activation purposes.

In the case of excited complexes formed of heterodimeric (two different) structural species, the official term for the resulting molecule is exciplex. Krypton-chloride (KrCl) exciplexes are desirable for their emission of 222 nm ultraviolet photons. The 222 nm wavelength is known for its excellent anti-microbial disinfection capabilities.

It is generally accepted that the term excimer can be used to describe the formation of both excimer and exciplex radiation, and has given rise to the term excilamp when referring to discharge-based excimer emitters.

Contact

How do excimer lamps work?

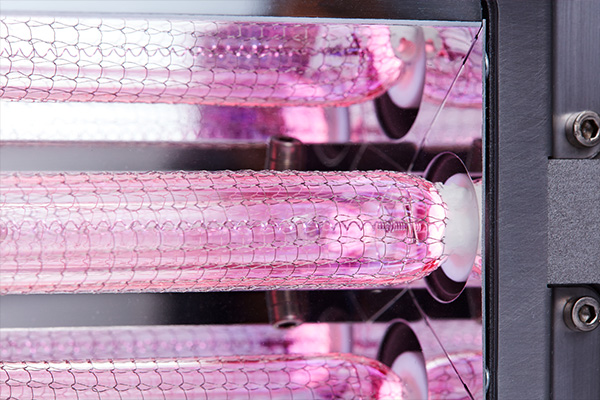

Excimer lamps are specially coated, noble gas-filled emitters which irradiate the desired vacuum-ultraviolet (VUV) wavelength, depending on which noble gases are present inside the sealed quartz glass chamber.

The external application of high-energy electrons into the lamp chamber generates an intense plasma discharge, also known as dielectric barrier discharge. The generated plasma contains high-energy electrons which can be immediately extinguished. The plasma induces the atomic excitement of the noble gas inside the lamp and triggers the formation of the excited dimers.

The final emission stage of the reaction is completed when the excimer molecules dissociate and return to their original ground state within a matter of nanoseconds, resulting in the emission of the excimer-specific UV radiation.

The emitted photons travel through the air, partly absorbed by oxygen to create ozone on the substrate. The ozone cracks the molecular bonds of the surface.

The cracked substrate molecules are partly removed, effectively leaving behind a chemically treated top layer. This effect is distributed along the length of Ushio’s excimer lamps, which can emit UV-C light at a wavelength of your choice from 172 nm to 310 nm. Depending on the desired wavelength, different noble gas combinations can be implemented within the excimer lamp chamber. All lamps can be customised and adapted to your needs by Ushio, during the manufacturing process.

222 nm far UV-C excimer is also gaining significant attention due to its ability to thoroughly disinfect surfaces. The significance of 222 nm is that it does not cause molecular disruption to organic tissue, unlike conventional 254 nm UV disinfection lamps. This means that 222 nm can be used in situations where humans are present. This wavelength is the key ingredient in Ushio’s Care222 UV disinfection solutions.

In industrial applications, the most commonly used excimer wavelength is 172 nm. Its energy of 7.23 eV is powerful enough to directly crack all major bonds of organic molecules, with the exception of bonds between carbon and oxygen (C=O) and some inorganic oxides. This makes it an excellent choice for surface modification, cleaning, and matting. Customers of Ushio’s ExciJet modules are primarily interested in this wavelength for their activities.

- The substrate surface is covered by contaminants which deactivate the surface, these contaminants may be organic matter such as fats and/or oxides.

- An excimer lamp calibrated to emit 172 nm radiation can directly crack the bonds of molecules on the substrate surface, residues of which remain on the surface.

- In the air gap between the excimer module and the substrate, high-energy oxygen radicals and ozone are produced after being excited by the 172 nm radiation. The radicals oxidise the residues and therefore the residues are removed from the surface.

Increase Surface Energy and Wettability with Ushio VUV Light

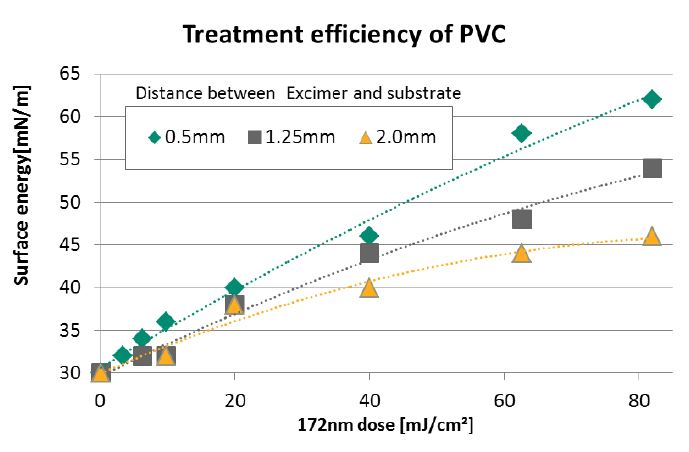

Excimer irradiation ‘activates’ the surface by increasing the surface energy, which is measured in millinewtons per metre (mN/m). Surface energy determines the contact angle between a fluid and a solid surface. To ensure adhesion and homogenous distribution, in applications such as printing and gluing, a smaller contact angle must be achieved.

- Fluid surface energy > Substrate surface energy: Poor wettability and adhesion

- Fluid surface energy = Substrate surface energy: 90° contact angle, average wettability

- Fluid surface energy < Substrate surface energy: Good wettability and adhesion

Surface Activation Energy Requirements

- Solvent inks: ≥ 34 mN/m

- UV inks: 36 - 42 mN/m

- Water-based colour systems: 38 – 50 mN/m

- Coatings: 36 - 42 mN/m

While the surface irradiation of polymers and other composite materials may be the most popular usage for excimer, the treatment is also applicable to almost any surface. Cleaning, coating, and bonding can also be significantly improved when applying excimer technology to silicon wafers, metals, and glass. In some cases, total hydrophilisation can be achieved in which wetting of the entire surface occurs. At this point, the contact angle of the liquid reaches zero degrees, transforming the drop of liquid into a liquid film.

An alternative to Corona and Plasma treatment

As an alternative to corona- and plasma-based surface treatments, excimer’s cold light drastically reduces the excess heat produced by comparable IR methods.

In fact, the IR emissions from excimer are almost non-existent, as is the presence of any thermal stress to the substrate. This reduced thermal load means no damage to the surface structure, which in turn assures better bonding results.

Corona and plasma are both electrical discharge methods, so the object being treated receives a heavier impact on its surface. Electrical discharge occurs when fluid in the air surrounding a conductor is ionised, which in the case of corona and plasma, is created by applying a high-voltage between two electrodes.

Instead, Ushio excimer lamps utilise VUV light to treat the surface, so there is no discharge reaction or damage to your substrates, nor is a significant heat load applied to the surface. Ultimately, this lower heat load makes excimer an ideal solution for temperature sensitive substrates, such as foils.

The photons emitted from an excimer lamp maintain a relatively low energy compared to the accelerated particles in other treatment methods, which makes a noticeable difference on the surface itself. This ‘softer’ approach means the substrate surface does not become rough like it does with corona and plasma.

Viewing a discharge-treated surface under an electron microscope will reveal a moon like surface with large scattered holes, as a result of molecular bombardment. When viewing the same material type after excimer treatment, the surface remains smooth, and benefits from a higher level of homogeneity.

Thanks to the absence of an electrical field, excimer does not suffer from dust contamination like the aforementioned alternatives, and can be applied to all electronics, which would otherwise suffer from static related issues associated with a discharge.

These desirable properties are supplemented by some welcome technical specifications:

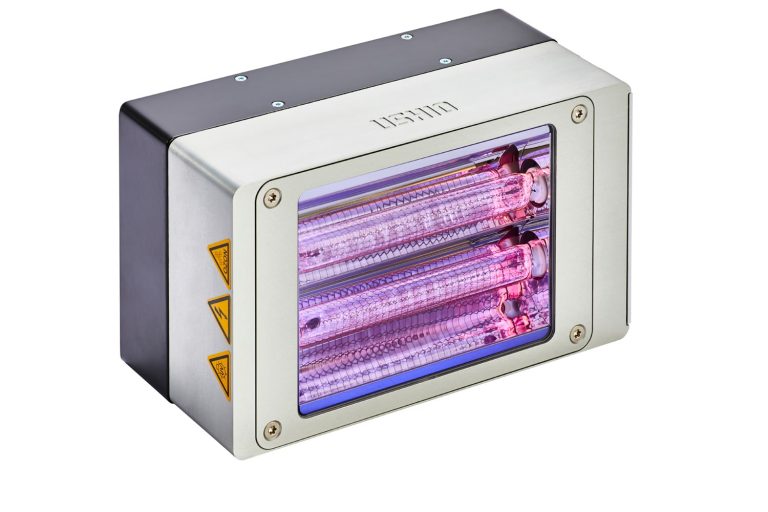

Introducing the Ushio ExciJet series

- Facilitation of line spectra and broad distribution

- Instant on / off functionality without heating or cooling cycles

- Compact size of ExciJet modules enables enhanced manoeuvrability

- Easy control system and built-in power supply

- Scalability allows for potentially unlimited lamps & modules

You may not realise it, but excimer is not a new technology. Ushio has been perfecting and discovering more applications for over a quarter of a century now, and the astonishing potential of excimer shows no sign of slowing. This has culminated in the release of its coveted ExciJet series which downsizes the technology to easily portable solutions:

- Compact, customisable plug-and-play modules for laboratory testing

- Robust, dimmable, mobile solutions for industrial applications

- High homogeneity and optimisation for the manufacture of semiconductors

- VUV output of over 170 mW/cm2 cleans up to 300 m/min in LED panel production

- Development & production satisfaction supplemented by an expert after-care team

Safe Far-UVC excimer technology is ready for human exposure

In general, ultraviolet light has the deserved reputation of being dangerous for humans, yet these wavelengths have beneficial uses. Mercury-vapour arc UV lamps are widely used in direct anti-microbial applications by emitting at 254 nm. At 254 nm, UV radiation gains enough intensity that it is able to penetrate the epidermal layer of skin and cause molecular changes in the layers beneath. These wavelengths are particularly damaging to the skin and eyes, leading in many cases to serious cases of mutation and illnesses such as cancer.

The excimer irradiation solutions from Ushio occupy customisable wavelengths between 170 nm and 310 nm, which are chosen for specific application suitability at each individual wavelength. Within the far-UVC region of 207 nm to 222 nm, it has been discovered that certain wavelengths are capable of disinfecting surfaces without causing the irreparable organic damage associated with other wavelengths.

222 nm has emerged as the safest for prolonged human exposure. At this range of intensity, the 222 nm UV radiation is unable to penetrate the top layer of skin or the eye-lens and simply deactivates any bacteria that may be present on the surface.

Our surface activation technology has been developed to concentrate 172 nm light on your chosen substrates. On the other hand, our PureRelease water purification component has proven 242 nm UV to be most effective in the instant disinfection of water at the point of dispensation (POD).

Experience VUV irradiation for yourself at Ushio’s Excimer Application Laboratory

Visitors to Ushio’s trade fair excimer demonstrations have been treated to exhibitions of surface activation, as various substrates were treated with an ExciJet 172 nm modular lamp, before revealing the result of an Ushio logo when displayed on the substrate when sprayed with water.

The live demonstration is typical of the applications tested at the Ushio Excimer Application Laboratory, and serves as an illustration of the simple set of processes Ushio follow to ensure optimal standards for your bespoke implementation.

Ushio’s excimer light technology allows the bonding of precision parts, such as optical & medical equipment, without adhesives or chemicals. By pressing two substrates together during treatment, a high strength and permanent bond takes place at a low pressure & temperature, with a faster annealing time.

The excimer technology developed by Ushio has already earned an excellent track record in the following industrial processes:

|

|

|

|

|

|

|

|

|

|

Bespoke excimer lamp and housing systems can be designed on request, unlocking the immense application possibility for various materials and surfaces. With an in-built power supply and completely flexible specifications, the excimer lamp & module solutions can easily adjust to your needs. Not only can Ushio help you find the right product for your needs, we share years of research to help make recommendations for process and execution.

- Broad length options & dimmable power ranges: 55 mm 9 W lamp up to 2 kW with our 2,600 mm lamps

- Unlimited lamp capacity, each individually calibrated for different spectra examination

- Phosphor-generated wavelengths from 170 nm – 350 nm

Ushio’s excimer lamp and modular solutions are the result of 30 years invested in research & development, and still, new application advances are being made constantly. A recent motivation of the research team has been to enable printing of 3D electronics directly onto a pre-treated surface.

This advancement looks set to bring significant implications for products which are heavily reliant on weight reduction, such as those in the automotive and aviation industries. Of additional interest to these two important industries, excimer is able to facilitate the adhesive-free bonding together of certain materials.

It is even possible to bond certain polymers to quartz glass! The chart below illustrates examples of glass, mineral, and polymer types that can be bonded using excimer technology.

Ushio excimer irradiation solutions improve product quality

Overall, it really depends on what your process requires. At Ushio, we are more than capable of giving informed advice to our clients, which is why they come back to us every time.

The benefits of excimer are clear, surface activation is useful for all kinds of applications but often choosing the wrong method can lead to expensive complications later.

Excimer is unique in that it allows irradiation without allowing an electrical discharge to make direct contact with the substrate surface. This means that the treated surface will hold on to ink, adhesive, or lacquer for longer.

Ushio is able to ensure that its highly qualified development and production teams are at your disposal for an in-depth problem study, thorough research analysis, and extensive testing. You will receive immaculate implementation after your go-ahead, putting Ushio’s customer-driven focus to the forefront of your business.

Where quality prevails, Ushio excels. Which brings us to the meticulous after-service provided by the team to secure a 100% satisfaction guarantee, and ensures the design & solution are delivered to your exact requirements.

Are you still not convinced? We already have some huge references from Ushio clients and partners regarding excimer technology, and we are happy to share them with you. Click the icons below each testimonial to learn more about Ushio’s excimer successes.

“Sterilising medical instruments is of the utmost importance – every upgrade could save another life. To ensure consistent quality and do one better every time, we turn to reliable partners. Like Ushio. Our medical disinfection devices with sterilisation rely on excimer technology for accuracy. The Ushio team provided us with multiple design proposals, which helped us make an informed decision on the best lamp selection to continuously move forward.”

Mr. Lucas Meyer

Chief Technology Officer at SteriLux SA

“We could not have achieved these results without the Ushio excimer technology. It was the missing compact piece to our puzzle. The Ushio team has been dedicated to this project from start to finish, their expertise and service has only intensified the outstanding results the excimer technology generated for the project. Excimer fixed our surface adhesion to achieve outstanding flexibility and transparency the PhotonFlex project required. Ushio made it happen in the best possible time, size and way.”

M. Sc. Ludwig Pongratz

Project Manager for Micro and Nano Structuring at Fraunhofer-Institute for Laser Technology