Semiconductor applications

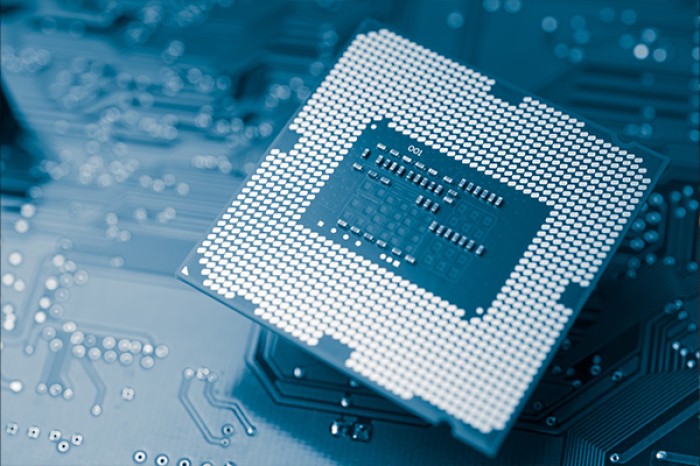

The semiconductor industry drives technological progress, powering everything from smartphones to cutting-edge computing systems. As demand grows for devices that are smaller, faster, and more energy-efficient, advancements in manufacturing processes become increasingly essential. Central to these processes are specialized light sources, critical for operations like lithography and photonics integration.

Lithography

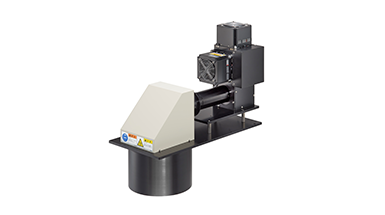

This process involves transferring intricate circuit patterns onto silicon wafers with unparalleled precision, creating the microscopic structures that enable modern electronics. As device miniaturization advances, achieving higher resolution in lithographic techniques has become a necessity.

Innovative light sources, such as lasers and plasma-based systems, have revolutionized the industry by enabling the precise patterning required for ever-smaller components. These advancements have made manufacturing processes more efficient and accurate, paving the way for the development of advanced chips that power industries like telecommunications, artificial intelligence, and quantum computing.

While lithography is a focal point, other essential processes must not be forgotten. Cleaning, wafer inspection, and rapid thermal processing (RTP) are equally critical to semiconductor manufacturing, each relying on advanced light sources for precision and efficiency.

Cleaning wafer surfaces

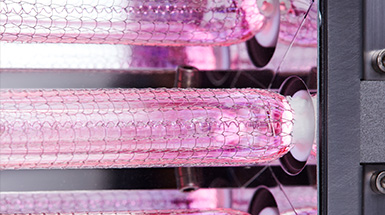

In cleaning processes, light sources such as excimer lamps are utilized to remove contaminants from wafer surfaces. These UV lamps facilitate photochemical reactions that break down organic residues and improve surface quality, a critical step before further processing.

Precise wafer inspection

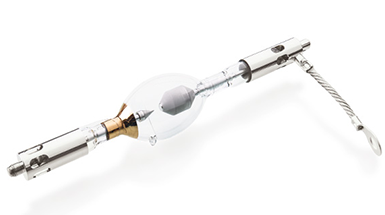

Wafer inspection, vital for ensuring quality and detecting defects, relies on bright, precise light sources like metal halide lamps and LEDs. These enable detailed imaging to identify flaws at nanometer scales, ensuring the reliability of final products.

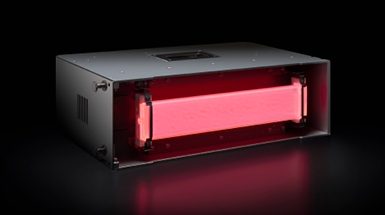

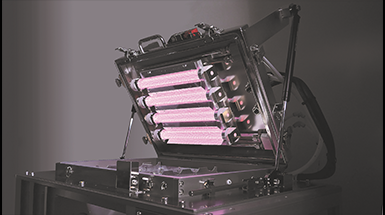

Rapid thermal processing (RTP)

During RTP, halogen lamps and infrared (IR) lamps are used to heat wafers quickly and uniformly for processes such as annealing and oxidation. Their ability to deliver controlled thermal energy is essential for maintaining wafer integrity.