Heating

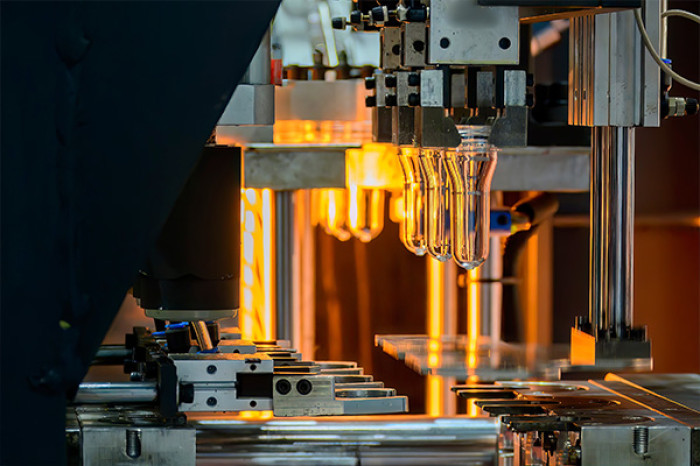

Heating processes are used in numerous industries and a sheer endless number of industrial manufacturing steps including thermoforming, PET blow moulding, drying of ink and paint, soldering, and catering to name a few.

Compared to convection systems, infrared heat (IR) provides excellent conditions to deliver efficient solutions thanks to the following advantages:

Zone heating

Applying heat precisely where it’s needed: Unlike convection systems that tend to apply heat not only to the targeted area but also to the surroundings, IR emitters' ability to confine heating to specific areas helps to maximize heating efficiency and allows to switch off heating locally in order to conserve energy.

Very short heat-up and cooling-off periods

Infrared systems often reach their operating temperature within a few seconds of being switched on. For processes in batches with changeover times, the system can therefore be shut down during the changeover. This minimises downtimes and energy can be used efficiently.

Contactless in-process heating

Infrared emitters apply heat contactlessly via infrared radiation keeping surfaces and objects clean, allowing for higher production speeds and less down time for maintenance.

Enhanced surface quality

Infrared heaters operate without direct contact with the target material, reducing the risk of contamination and physical damage. This is essential for maintaining product quality, particularly in high-precision applications.

Minimised oxidation and contamination

Because infrared heating systems operate without combustion, they generate minimal by-products. This lowers the risk of oxidation and contamination on the target material, which is crucial for preserving high purity and quality.

Eco-Friendly

Infrared heating generates fewer emissions than traditional gas-fired furnaces, leading to a cleaner working environment and aiding glass manufacturers in complying with stringent environmental regulations.

Expert Knowledge and customized solutions

Efficient infrared lamps can convert more than 90% of the total electrical input power into radiation. For maximum process efficiency, the target material must possess an absorption comparable to the spectrum emitted by the IR lamp. Ushio has a long track record of supporting customers find the most suitable lamp for their application.

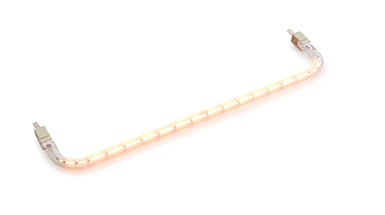

With more than 60 years of experience in the lighting industry, Ushio offers a wide range of IR emitters, including pin-type lamps, linear single, double, and twin tube emitters, as well as shaped and bent forms. Customers can select from a wide range of coatings and even filaments, allowing for tailored solutions developed for specific needs and process steps.

Our specially trained engineers at Ushio’s R&D and production facilities in Germany and Poland devise, build and test every lamp. This ethos results in products that are perfectly matched to customer requirements every time.

| Applications: | ||

|

|

|