Oude Meer, March 2018 – In the last decade, excimer radiation sources have gained more and more

impact in many fields of surface cleaning, surface activation and hydrophilisation like semiconductor

and flat panel display production but also in exotic applications like the photofunctionalisation of human

implants for an enhanced healing pace. All these applications are based on the effect of high-energy

radiation in combination with oxygen radicals which are made out of the air by the radiation.

Process based on high-energy photons

The treatment works in a two-step process in which biological contaminants are removed residue-free

from all kinds of surfaces. In a first step, the chemical bindings of the organic molecules are directly

cracked by 172 nm radiation. In the second step, the residues from the split molecules are removed

from the surface by radical oxygen and ozone which is generated by the 172 nm radiation out of the

thin air layer between the module and the surface.

The advantages of this technique are that there are no dusts created and that the process does not

damage the surface or heat it up.

In general, the technique works on all kind of substrates, while originally mainly glass, silicon and

other metals were cleaned.

For polymers the cleaning works as well in a way that process contaminations as well as the first

adsorption and reaction layers on the polymer with lower surface energies are removed. In addition,

it was demonstrated in XPS analysis, that the oxygen content of the surface layers are partly significantly

increased (e.g. 5% to 35% with PVC) which also improves the quality for bonding processes

afterwards.

No damages to the thin layers

Ushio’s excimer radiation is already known for surface activation and cleaning.

What is new:

Excimer radiation can also be used very efficiently on existing coatings like functional coatings or

lacquers.

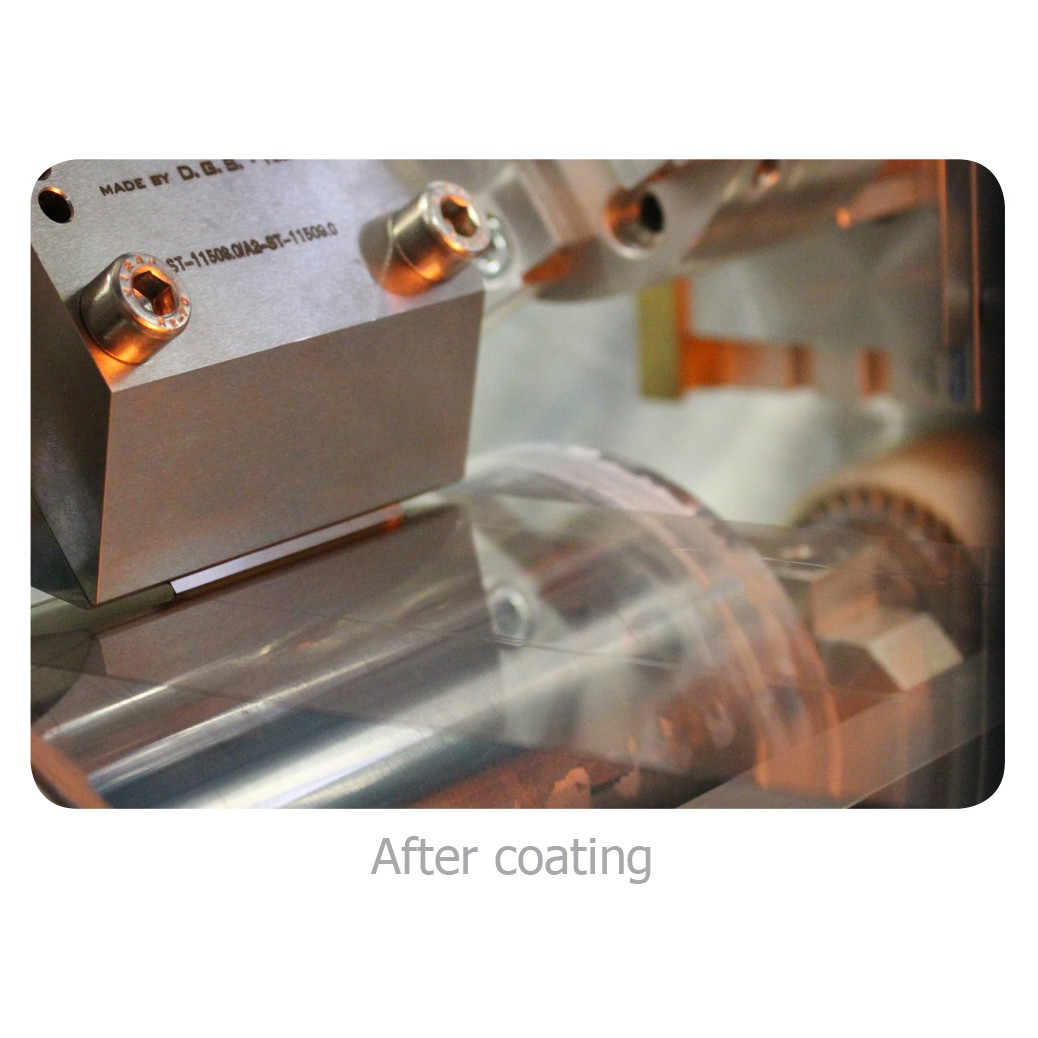

One recent and widely applicable example is the treatment on ITO before the coating with water

based light-sensitive polymer layer in the PhotoFlex project to produce organic solar cells (http://

www.lat.rub.de/inhalt/forschung/photonflex.html). During this test the surface energy from the ITO

Before coating After coating

2

Succes Story: Sunshower

on PET could be enhanced from only 25mN/m to up to 70mN/m in a roll to roll application. Only with

excimer technology it is therefore possible to coat the thin Ito layer (100nm thickness range) as any

other treatment method would destroy the sensitive film.

No gaps

In the comparison you can directly see, that there is an ideal wetting with the treated foil (right), while

the coating liquid sticks to the nozzle for the untreated foil.

The measurements also show, that the film on the treated ITO is homogeneous and without any gaps.

With this technique, it is possible to create too, innovative material combinations. With applying

masks, it is even possible to treat only specific pattern on the substrates so that the material is only

treated where needed or even functional patterns can be created.

Creating functional patterns is possible

Excimer radiation can be shaped with mask in the range of μm with the help of masks. On the one

side this can enable processes, in which only selected areas of already processed chips are treated

while other, sensitive areas are not affected.

In addition, it is even possible to create organic semiconductor components like transistors while

treating a hydrophobic layer on the substrate with an excimer light pattern. Afterwards a metal nano-

ink is applied, which is only attached to the areas illuminated before. This pattern then form the

organic semiconductors as for example published by Takeo Minari.

Excimer Application Laboratory

As part of the portfolio of solutions that are currently offered by Ushio, customers are able to utilize

an in-house, bespoke Excimer Application Laboratory to test Excimer applications, hone application

designs, achieve insight and technical knowledge, and pave the way for ground-breaking innovation

within Excimer applications.

For more information on how Ushio can collaborate and work together with you to achieve excellence

through use of the Excimer Application Laboratory, please contact Mr. Andreas Schäfert at excimer@ushio.eu

Read Press Release PDF: Ushio’s excimer technology enables organic cell production – enables coating of thin Ito layers – enables innovative material combinations