Ushio’s IR Application Laboratory allows extensive material testing by clients

Ushio customers are able to make use of a bespoke Infrared (IR) Application Lab to test IR applications, hone application designs, achieve insight and technical knowledge, and pave the way for ground-breaking innovation within IR applications.

The IR Laboratory, based in Steinhoering, Bavaria, is a hive of intensive in-house research, conceptualisation and design. The lab gives prospective customers a total solution, from product to consultation, and unparalleled in-house expertise all under one roof. The project, spearheaded by Ushio Germany’s IR experts, is an opportunity to bring minds together and improve existing infrared designs, optimise existing infrared processes, and thoroughly analyse infrared performance under laboratory testing conditions. As part of Ushio’s the IR lab package, the customer can benefit from the expert guidance and consultation of Ushio’s dedicated technical team who bring an unrivalled knowledge of IR heating and irradiation technology.

“Collaborate to create something remarkable, together.”

“Ushio is wholly committed to creating partnerships with customers, developing and strengthening relationships, and achieving a deeper understanding of exactly what it is that the customer requires. The IR Application Lab is just one example which illustrates this perfectly. We work together with customers to identify a weak spot or just a general area for improvement and then further collaborate to create something remarkable, together.

The lab is a platform for collaboration and joint investigation and analysis of IR processes providing various setups that emulate customer production environments. This simulation environment is the catalyst to perform experiments which can rarely be realised at the customers own environment. We recently worked together with a customer and used the IR Application Lab as a tool to investigate their current IR processes and the results were truly fantastic; through analysis driven optimisation, more than double the previous performance was eventually achieved.” Says Dr. Brandstetter.

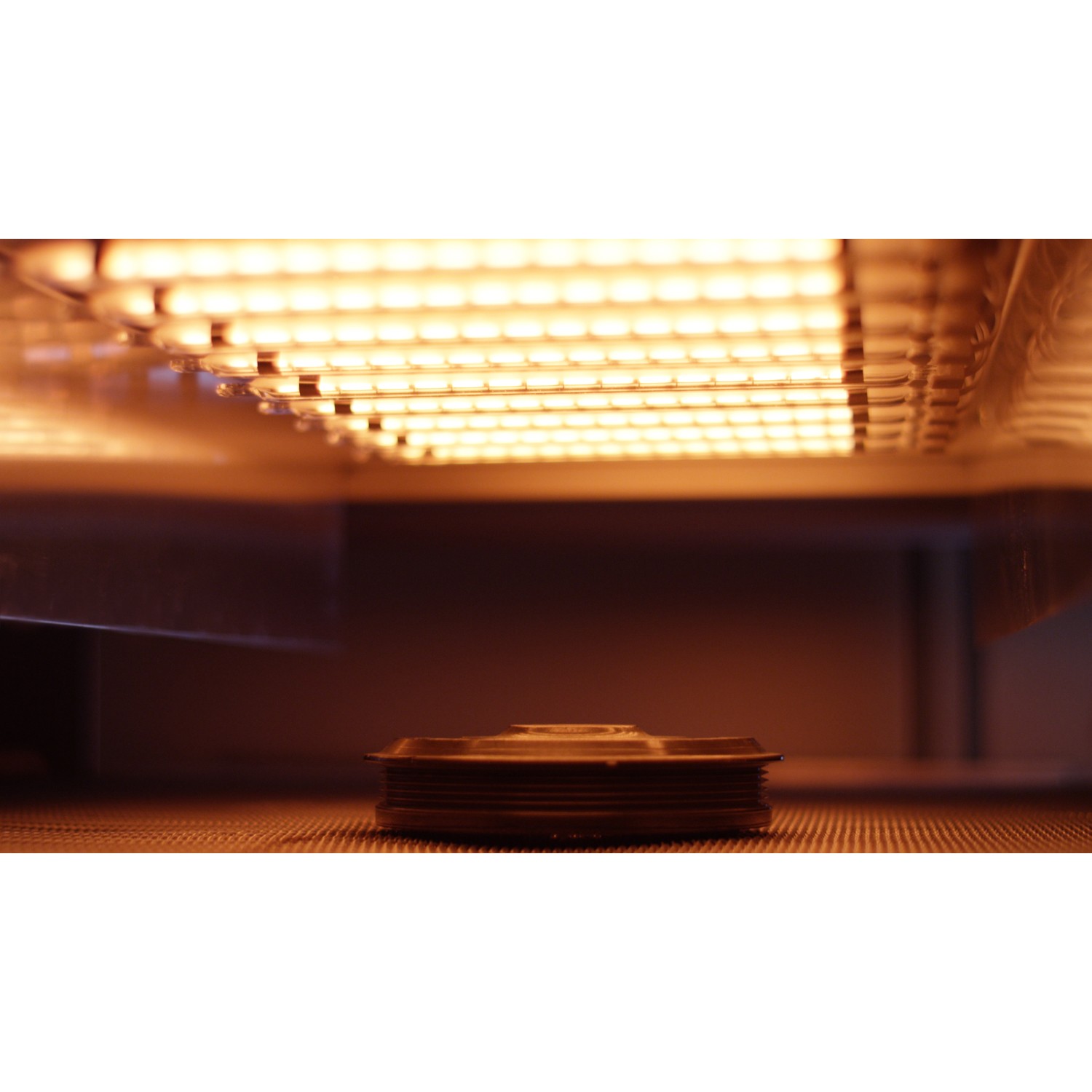

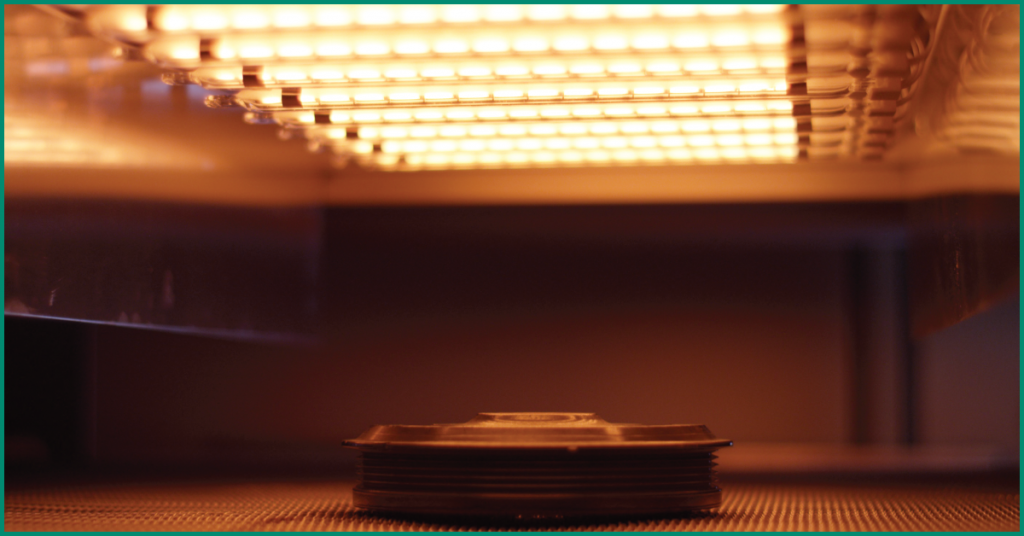

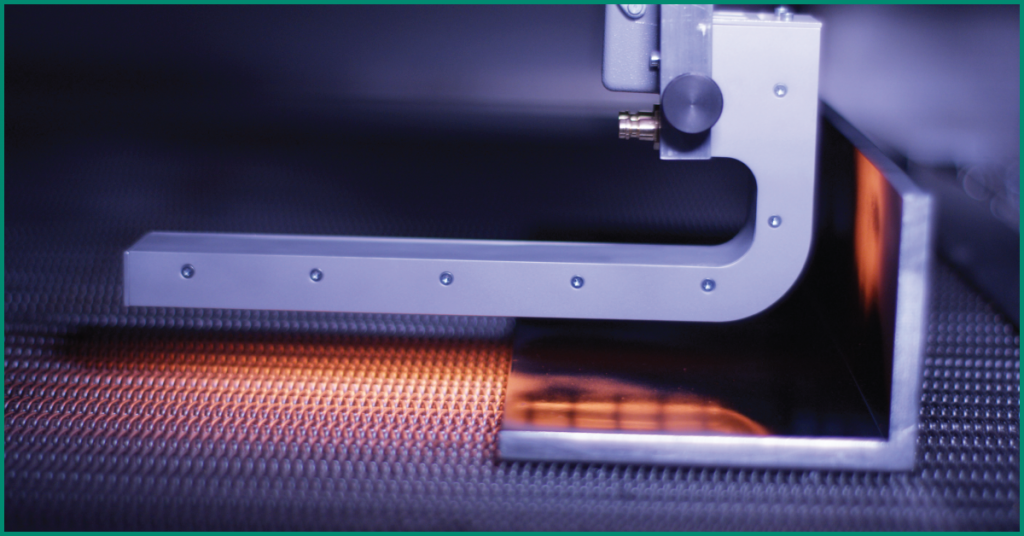

Ushio IR Application Lab equipped with a conveyor belt system and 2D scanning device

The lab houses an adjustable conveyor belt system used to transport customer materials and products, capable of mounting various types of Ushio IR equipment. Furthermore, a 2D scanning device measures radiation patterns of the IR lamps and modules in 2 dimensions. This enables the investigation, analysis, and optimisation of IR equipment designs. For acquisition, visualisation, and analysis of measurement data, the IR application lab is equipped with an array of sensors and detection tools.

“We have found that 1-2 days is adequate time for testing in the laboratory, resulting in significant process improvements for the customer whilst simultaneously reducing development efforts on the customer’s part.” Explains Dr. Brandstetter

The laboratory portfolio is growing in line with demand for this highly specialised service

The IR Application Laboratory is just one of the facilities available at the Steinhoering site. Other testing facilities exist for conventional UV, UV LED, and a new excimer / VUV testing laboratory has been built to meet the growing demand for this specialised service offered by Ushio.

For more information on how Ushio can collaborate and work together with you to achieve excellence through use of the IR Application Lab, please visit our contact page. Alternatively, email Sales Director Thomas Haider and his team at ir@ushio.eu.