Different methods of surface treatment – a comparison

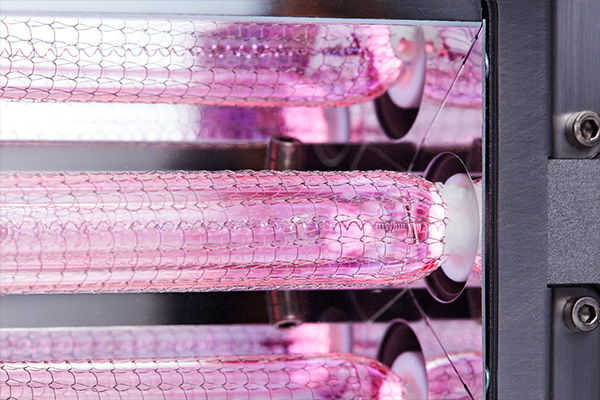

Corona surface treatment is a type of atmospheric-pressure plasma generated by applying high voltage to an electrode opposite a grounded roll (or plate) while a substrate passes through the discharge zone. The discharge ionizes ambient air and creates a low-temperature plasma containing reactive oxygen- and nitrogen-based species.

These reactive species interact with the top few nanometers of polymer surfaces and typically increase surface energy via mild oxidation and related chemical modifications (e.g., introduction of polar groups). The result is improved wettability and adhesion; effects and dose–response have been reported for PP, PE, and PET films.

The process imparts some thermal and energetic load to the surface, but—under typical web-treating conditions—its principal action is chemical functionalization rather than physical “sputtering” removal of material. Reported changes include modest topography evolution without bulk thermal property changes.

Corona systems are widely used for in-line treatment of webs and sheets (e.g., plastic films) and can also be configured for molded parts; they are valued for simplicity and compatibility with roll-to-roll production.

Compared with other technologies (e.g., atmospheric jet/plasma systems, vacuum plasma, or excimer UV at 172 nm), corona generally offers less control over surface-specific chemistry because it relies on air plasma with a broad mix of species. By contrast, excimer UV is wavelength-specific and can drive near-surface photochemistry with low penetration depth. Technology choice depends on the substrate and target functionality.

A known operational issue is electrostatic charge on treated insulating webs. Elevated charge can attract airborne dust, cause ESD-related process disturbances, and—in sensitive environments—pose safety risks. Charge can be mitigated with ionizing bars/blowers or similar neutralizers placed along the web path.

Plasma Surface Treatment

Plasma surface treatment is a process used to modify the outermost layers of a material through exposure to a partially ionized gas — a plasma. The plasma consists of ions, electrons, radicals, and excited neutral species generated when a gas is energized by an electric field. Depending on the setup, the process can take place under atmospheric or low-pressure (vacuum) conditions, using gases such as air, oxygen, nitrogen, argon, or specific gas mixtures.

Within the plasma, reactive species interact with the substrate surface and induce chemical and physical modifications. These may include the incorporation of polar functional groups, surface cleaning through removal of weak boundary layers, or mild surface etching. The overall effect is an increase in surface energy and improved adhesion, wettability, or coating compatibility, without affecting the bulk properties of the material.

The interaction depth is limited to only a few nanometers, and the energy transfer to the surface is moderate. Because the process parameters — including gas type, pressure, and power — can be precisely controlled, plasma treatment offers fine-tuned modification and reproducible results.

Two principal process types are used in industry. Atmospheric plasma systems operate in open air or controlled gas atmospheres and are suitable for in-line processing of films, molded parts, or other three-dimensional components. Vacuum plasma systems, by contrast, work in sealed chambers at low pressure, enabling uniform treatment, higher plasma density, and controlled surface chemistry for more demanding or delicate applications.

Compared with corona treatment, plasma systems generally achieve higher concentrations of reactive species and more uniform surface modification. They provide greater control over the chemistry of the treated surface, which makes them suitable for a wider range of materials and geometries.

Typical applications include surface activation of polymers prior to bonding or coating, precision cleaning of metals and glass, and preparation of materials for thin-film deposition or encapsulation.

The main limitations of plasma treatment are the higher system complexity and cost compared to corona technology. Vacuum plasma processes also require batch operation, which can reduce throughput in continuous production environments.

Excimer Surface Treatment

Excimer surface treatment is a photochemical process that modifies material surfaces using short-wavelength ultraviolet (UV) radiation. The treatment is typically carried out with xenon excimer lamps emitting at 172 nanometres, a wavelength strongly absorbed by most organic materials. The process operates at atmospheric pressure and does not require vacuum or high voltage.

When the UV photons strike the surface, they break molecular bonds within a very thin surface layer — usually only a few nanometres deep. This photochemical interaction initiates oxidation and cross-linking reactions with ambient oxygen, resulting in the formation of new polar functional groups on the surface. These chemical changes increase the surface energy of the material, improving its wettability and adhesion characteristics.

Unlike plasma-based methods, excimer treatment is a purely photochemical process. There is no ion bombardment or particle impact, and therefore no physical erosion or heat damage to the substrate. The treatment is considered “cold,” making it suitable for temperature-sensitive materials such as thin polymer films or microstructured surfaces.

Excimer technology offers precise control of the reaction, as the photon energy and penetration depth are defined by the wavelength. This allows selective modification of surface chemistry without altering the bulk material or underlying coatings. When combined with an inert or controlled gas atmosphere, the process can further tailor oxidation levels or suppress ozone formation.

Typical applications include surface activation and cleaning of polymers, glass, and semiconductor materials; preparation of surfaces for coating, bonding, or printing; and the smoothing or functionalization of thin films and photoresists. Excimer lamps are also used in microelectronics and display manufacturing, where uniform and damage-free surface modification is required.

While excimer treatment provides exceptional uniformity and precision, system complexity and cost are higher compared with corona or basic plasma technologies. Throughput can also be limited for very large surface areas due to the optical configuration and required exposure time.

Run tests in the Excimer laboratory at our site in Germany

The completion of the Ushio Application Laboratories in Germany marks a significant milestone, offering clients the opportunity to test our solutions on their own materials under tightly controlled conditions. Situated in Steinhöring, Germany, these laboratories invite prospective clients to explore industrial Excimer processes in detail.

If your application is predestined for excimer treatment and you decide to use it, we offer to treat samples of the corresponding materials in our in-house test laboratory according to your catalog of requirements. We also welcome you on site to conduct these tests together. Our experts will provide you with detailed test reports in any case and define adaptation possibilities together with you, should these be necessary or desired.

If you would like to have final tests at your site, we also offer the possibility - under certain conditions - to borrow excimer test modules and to test them directly in the real-world environment with our expert advice.

And even after the start of the project, we continue to advise and support our customers. We help, if necessary, with the practical integration of the modules into your production line. And should small adaptations or modifications be necessary for optimal integration, we also have the appropriate know-how.

The excimer technology developed by Ushio has already earned an excellent track record in the following industrial processes

- Surface activation

- Surface cleaning

- Surface modification

- UV curing

- Matting

- Curing nanocomposite coatings

- Optical, adhesive-free bonding (Photobonding)

- Photochemical or biological modification of gases, liquids, etc.

Fields and Industries Implementing VUV Excimer Surface Treatment

- Aerospace

- Automotives

- Engineering

- Food and Beverages

- Forensic Science

- Medical Science

- Microelectronics