Postponement of another trade show fails to dampen Ushio’s UV LED and excimer printing solution targets

After months, and in some cases, years of preparation, industries across the world have looked on in horror as the COVID-19 pandemic has triggered a domino effect and toppled 2020’s first half trade show calendar. The printing industry is no different; with the inevitable postponement announced, delaying the DRUPA printing technologies event until 20 – 30 April 2021. In the face of potential setbacks materialising as a result of these developments, Ushio Europe is determined to continue planning for the future, and has committed to presenting its renowned lighting solutions at the rescheduled trade show in Düsseldorf.

Despite the cancellation of many in-person meetings during the current health crisis, Ushio Europe remains fully operational and awaits the opportunity to advise and recommend its bespoke solutions to businesses across the EMEA region.

As a market leading manufacturer of industrial lighting solutions, Ushio has consistently pushed the boundaries of technology since first incorporating, in 1964. Over the last half century, the company has established its expertise across the spectrum, from ultraviolet (UV), through visible (VIS), to infrared (IR). With the development of new printing technologies increasing exponentially, Ushio has selected its shortlist of the most influential applications in which its component solutions excel:

-

- Curing (UV LED / conventional UV / IR)

- Surface science / pre-treatment (Excimer)

- Sensors (Laser Diodes)

- Application knowledge (Ushio’s Technical Development Team)

UniJet UV LED modules will bring versatility to 3D & inkjet curing at DRUPA 2021

As the relatively new UV LED technology takes over the driving seat from conventional UV, Ushio has found success with its customisable UniJet modules. Designed for the highest performance in printing, curing, and image processing, UniJet has been launched in three distinct lines. The UniJet A, E, and i-Series have been developed specifically with the commercial and industrial printing industries in mind. DRUPA 2021 visitors will have the opportunity to speak directly with Ushio representatives who have first-hand experience of using these devices, with the flagship UniJet E-Series taking centre stage on this occasion.

The entire range of Ushio’s UniJet UV LED modules holds a clear advantage over their traditional UV curing counterparts. With a total absence of mercury within the device and the complete eradication of ozone emissions, UniJet offers safer operation conditions while ensuring unprecedented energy efficiency. The compact and easy to operate UniJet units are designed to remain fully operational for over 10,000 hours of use, and are available with either water or air cooling.

UniJet E-Series UV LED modules allows customised optical system combinations

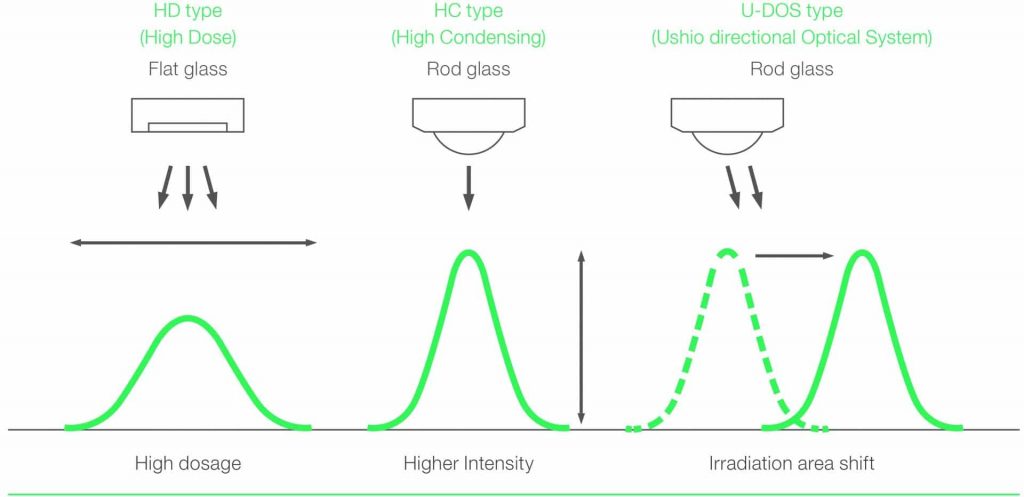

The air cooled UniJet E-Series modules have proven themselves to be particularly adept when installed within an inkjet or 3D printing device. Offering three varieties of UniJet E-Series modules, Ushio has developed three different optical systems to allow the user to choose the most suitable intensity distribution for their particular application. Up to three standard E-Series modules can be linked together, while the E II-Series modules can be linked in pairs.

UniJet E-HD (High Dose)

The UniJet E-HD offers a high dose of accumulated irradiance which makes it the ideal solution for deployment in quick drying applications, such as inkjet printers.

UniJet E-HC (High Condensing)

Focusing the light using an integrated rod, the UniJet E-HC is able to achieve higher peak irradiance than the E-HD. The High Condensing model is most suitable for UV curing and other side emitting applications.

UniJet E-U-DOS (Ushio Directional Optical System)

The UniJet E-U-DOS model offers a shift in the irradiation area angle, which in turn provides effective light focus. This unique technology prevents clogging in the print head.

Air-cooled UniJet E-Series – the star of the show?

- Mercury-Free

- Ozone-Free

- Energy Efficient

- Compact Design

- High Peak Irradiance

- Dimmable

- Long Life > 10,000 Hours

- Air Cooled

- Available Wavelengths: 365nm, 385nm, 395nm, 405nm

For full specifications of the UniJet series, please download the brochure here. You can also contact our UV LED experts directly by visiting our contact page.

Printing onto sensitive materials and electronics made easy with Ushio excimer technology

Within the printing world, the problem of ink adhesion longevity has long been a sticking point, especially in the case of printing onto plastic objects, such as credit cards. Many plastics are fairly hydrophobic, which means their ‘wettability’ is very low. As a result, certain surface irradiation techniques have been developed to increase the wettability of a surface, and therefore, improve long-term ink adhesion. Despite their advantages, and proven ability to increase ink adhesion, the widely used corona and plasma surface irradiation techniques display some clear drawbacks, when compared to Ushio’s emergent excimer technology.

Corona and plasma irradiation are both popular industrial surface activation treatments. Each of these treatments involves applying an electrical discharge reaction directly onto the surface. As a result, the substrate is subjected to a rather violent ionic bombardment, which leaves charged molecules embedded in the surface. Viewing a discharge-treated surface under an electron microscope reveals a moon-like surface, scattered with large uneven craters. This effect, a result of the molecular bombardment, is irreversible. While the surface is successfully irradiated, and ink adhesion is certainly improved, the end result still leads to reduced ink adhesion longevity.

A secondary issue with electrical discharge-based surface treatments is the generation of static charge. A powerful static field, such as that produced by corona treatments, can attract dust particles from several metres away, as well as having the unfortunate ability to fry any nearby electronic circuits. Aside from the potential contamination and circuit damage issues, the attracted dust particles can become ‘stuck’ to the surface prior to ink application. Should the printing process proceed without removing these particles, ink will then be applied over the dust layer. At first, little difference can be seen but over time these particles will fall away, taking the ink along with them.

Ushio’s ExciJet modules improve ink adhesion at DRUPA, with “softer” excimer surface treatment

Excimer utilises low-heat vacuum-ultraviolet (VUV) irradiation to optimise the surface conditions for printing. There is no direct discharge reaction, and therefore, no damage to your substrates. The photons emitted from the excimer lamp maintain a relatively low energy compared to the accelerated particles in other treatment methods. This softer approach means the substrate surface does not become rough, a far cry from the damage caused by corona and plasma.

When viewing an excimer treated substrate through an electron microscope, the surface is noticeably smoother, benefiting from a higher level of homogeneity, thereby promoting enhanced adhesive qualities. Additionally, the absence of an electrical field means excimer does not suffer from dust contamination like the aforementioned alternatives, and can be applied to all electronic devices, which would otherwise suffer from static related issues associated with a discharge.

Proven applications for Ushio excimer

- Surface activation

- Surface cleaning

- Surface modification

- UV curing

- Matting

- Disinfection

- Photobonding™ (Optical, adhesive-free bonding)

- Removal of organic contaminants from production processes

- Photochemical or biological modification of gases, liquids, etc.

- Treatment of sensitive materials

Ushio’s excimer surface science solutions will demonstrate at DRUPA 2021

A huge missed opportunity this year was the opportunity for DRUPA delegates to see a live demonstration of Ushio’s vacuum-ultraviolet (VUV) excimer lamp technology. With an adjustable wavelength range of 170 nm to 310 nm, the Ushio ExciJet series has certainly caught the attention of industry leaders across the globe. Bringing significant improvement to surface activation treatments, the units pass on an added bonus to production with simultaneous disinfection on any treated surface.

Ushio ExciJet series capabilities

- Facilitation of line spectra and broad distribution

- Instant on / off functionality without heating or cooling cycles

- Compact size of ExciJet modules enables enhanced manoeuvrability

- Easy control system and built-in power supply

- Scalability allows for potentially unlimited lamps & modules

- Compact, customisable plug-and-play modules

- Robust, dimmable, mobile solutions for industrial applications

- High homogeneity and optimisation

- VUV output of over 170 mW/cm2

- Development & production satisfaction supplemented by an expert after-care team

- Wavelength range: 172 nm – 310 nm, adjustable.

Ushio’s growing excimer technical development team will be out in force at DRUPA, ready to demonstrate and discuss how you can integrate this technology into your own devices, production lines, or as an experimental unit for testing. Known for being highly adjustable and often custom-made to the specifications of each client, Ushio products and solutions continue to be available and will break new ground throughout 2020, 2021, and beyond.

If you would like to make your own enquiries prior to the show, please direct them to us through our contact page.

Further Reading

Ushio Excimer Irradiation Solutions brochure

Ushio UniJet UV LED Solutions brochure

Excimer: The Technology Explained – An Ushio learning resource

Surface Treatment Alternatives For Sensitive Substrates – An Ushio learning resource